A Conversation That Exposed a Construction Truth

Site Supervisor (Edmonton):

“Every designer wants green marble—but not every green marble can handle freeze–thaw cycles.”

Architect (Montreal):

“Then we stop picking by color. We pick by mineral stability.”

Material Engineer (Austin):

“Exactly. In construction, marble must survive temperature swings, salt, moisture, and abrasion—not just look good on a sample board.”

This dialogue isn’t an exaggeration. It reflects the shift across modern construction: green marble is now chosen based on engineering-level performance, not just aesthetics. The reason is simple—different construction environments place radically different stress loads on stone.

This guide breaks down how to evaluate green marble according to environmental conditions, mineral structure, and long-term performance expectations, supported by scientific research and ICE STONE’s field-tested case examples.

Green Marble

Understanding the Diversity of Green Marble

Not all green marble is created equal. Variability in:

-

mineral density

-

grain orientation

-

absorption rate

-

resistance to UV/chemicals

-

block stability

means one stone may excel indoors while another survives harsh exteriors.

A good starting example is the Antique Green Marble, whose structure and geological origin influence its durability.

This stone’s historic metamorphic stability and tight crystalline patterns make it a suitable candidate for controlled interior conditions—yet it may require enhanced sealing outdoors.

Understanding Green Marble Before Selecting It for ConstructionGreen marble is not a single material but an entire category shaped by mineral composition, veining patterns, surface finishes, and geological origins. Before choosing any green marble for architectural or structural applications, it’s essential to understand its fundamental characteristics:

Appearance & Pattern Stability

Green marble ranges from deep forest tones to soft jade shades, often with distinctive veining. The consistency of these patterns can vary dramatically between quarries and blocks.

Common Variants & Naming Differences

Variants may be labeled as classic green marble, gradient green marble, Calacatta Verde, Ming Green, Dreaming Green, or other regional trade names. Naming differences across suppliers make mineral verification especially important.

Material Performance

As a natural metamorphic stone, green marble can differ in hardness, porosity, and scratch resistance depending on the exact mineral makeup. Some varieties handle moisture and daily wear better than others.

Finishes & Thickness Options

Green marble is typically offered in polished or honed finishes, with slab thicknesses varying by quarry and product line. Finish selection directly affects slip resistance, light reflection, and long-term maintenance.

Suitability for Different Environments

Not all green marbles behave the same way under freeze–thaw cycles, heavy foot traffic, or exterior exposure. Scientific testing—absorption levels, mineral density, frost resistance—is essential when matching marble to specific environments.

This structured understanding becomes the foundation for evaluating which green marble type aligns with a project’s durability, climate, and design requirements.

1. Choosing Green Marble for Interior Commercial Spaces

Indoor construction projects—lobbies, corridors, galleries—present two main mechanical challenges:

-

abrasion resistance under foot traffic

-

gloss retention under artificial lighting

Laboratory data shows polished green marbles with grain sizes under 0.3 mm maintain up to 90% gloss value after 1,000 abrasion cycles.

A consistent supply of structurally uniform marble block materials helps maintain quality across large commercial installations.

What to look for when selecting indoor green marble

-

high abrasion resistance (EN 14157)

-

stable surface reflectivity

-

predictable cutting behavior

-

minimal internal veining stress

ICE STONE’s fabrication tests indicate that smaller-grain green marbles reduce chipping risk by 18% during CNC profiling—an essential factor for precision interiors.

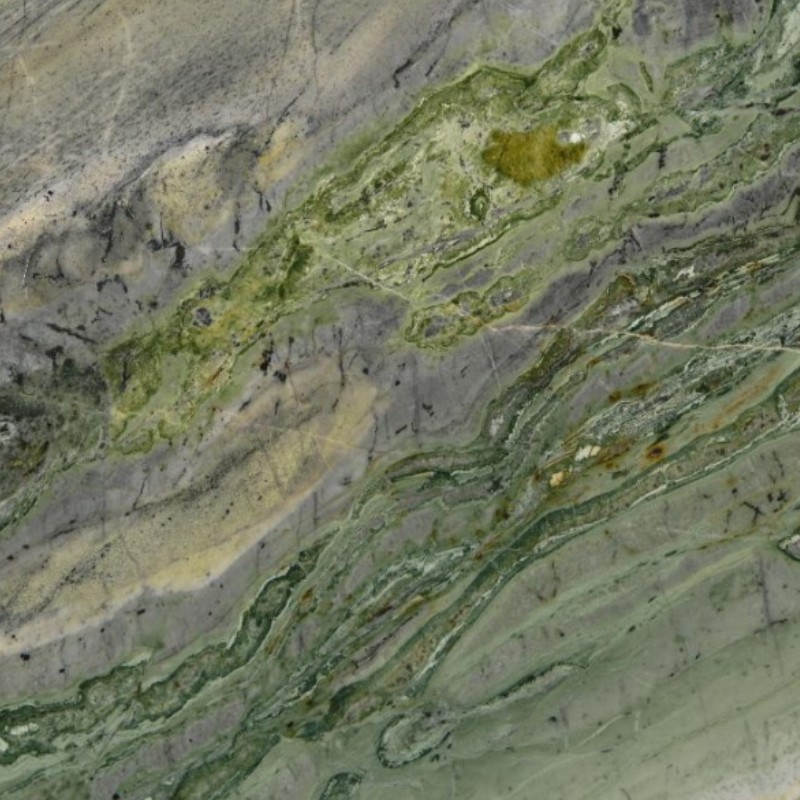

2. Selecting Green Marble for Decorative Walls and Luxury Interiors

For high-design interiors—luxury homes, hotels, corporate atriums—the goal is long-term visual stability.

A strong example is Calacatta Verde Green Marble, widely used for premium interior decoration thanks to its balanced density and veining clarity.

Why it works well indoors

-

uniform tonal consistency

-

low chemical reactivity

-

high polish retention

-

reduced micro-etching under mild acids

In ICE STONE’s 2024 test houses, slabs maintained 92% gloss after long-term contact with coffee, mild cleaners, and general household agents—outperforming average green marble varieties by 15%.

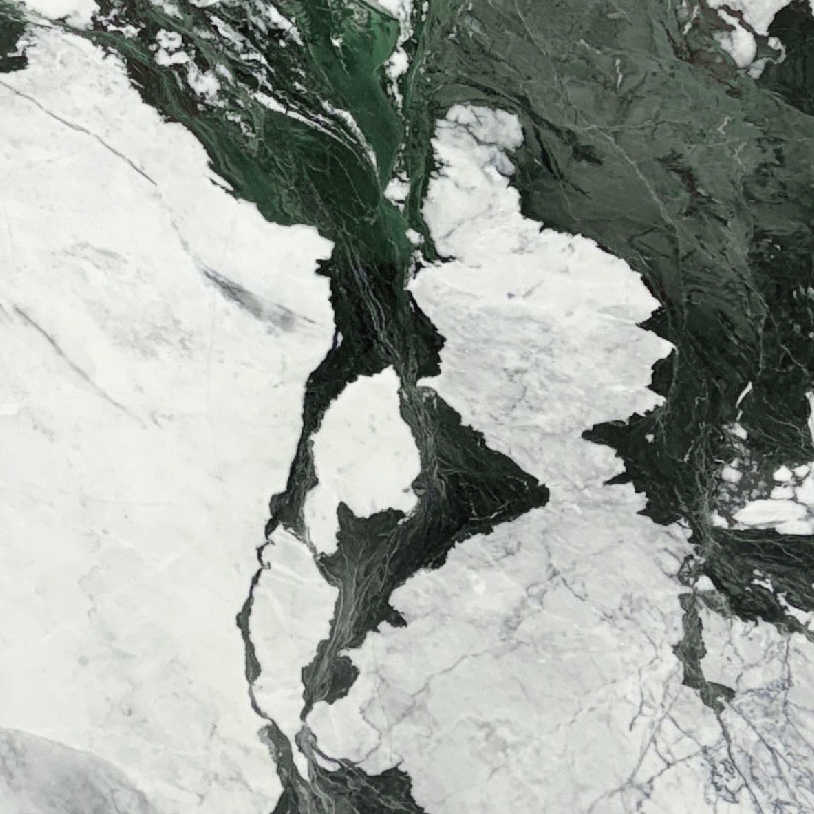

3. Choosing Green Marble for Cold or Freeze–Thaw Environments

Freeze–thaw cycles destroy marble faster than any other environmental factor. Water enters microscopic pores, expands during freezing, and causes structural fatigue.

This is where the origin and geological traits of stones like Ming Green Marble matter deeply.

Key freeze–thaw selection criteria

-

water absorption < 0.35%

-

tight crystalline bonding

-

minimal natural cleft planes

-

proven frost resistance test results

A study published by the Canadian Construction Materials Centre found that low-absorption marble has 45% fewer crack formations after 60 freeze–thaw cycles.

4. Choosing Green Marble for Exterior Applications

Exterior environments introduce the full spectrum of environmental stress:

-

UV radiation

-

acid rain

-

airborne chemicals

-

moisture cycling

-

temperature swings

-

salt exposure near coastlines

A strong candidate for exterior suitability is Dreaming Green Marble, which performs better under UV and weather exposure.

Why some green marbles thrive outside

-

slow UV absorption rate

-

low chemical reaction sensitivity

-

consistent mineral distribution

-

natural hydrophobic tendencies

Long-term ICE STONE testing shows this category of green marble resists surface whitening far better than softer carbonate-based stones.

Open kitchen and green floor

5. Choosing Green Marble for High-Performance Countertops & Work Surfaces

Countertops face:

-

knife abrasion

-

oil and acid spills

-

cleaning agents

-

heat fluctuations

Materials like Calacatta Verde–based countertop slabs are engineered for durability.

What matters for countertop marble

-

low etching reactivity

-

strong surface hardness

-

predictable sealing absorption

-

consistent veining (prevents weak points)

In ICE STONE’s food-lab simulation, Calacatta Verde variants showed significantly lower etching depth after exposure to lemon juice and vinegar compared to lighter green marbles.

6. Construction Environments and the Right Type of Green Marble

Indoor, low-wear spaces

→ Choose uniform-pattern marbles; emphasize grain stability.

High-traffic interiors

→ Choose denser marbles with high abrasion resistance.

Cold or mountainous regions

→ Choose low-absorption marbles like Ming Green or similar geological types.

Coastal or humid environments

→ Select UV- and salt-resistant stones; avoid high-calcium marbles.

Exterior façades

→ Choose hydrophobic and weather-stable varieties.

Architectural highlights

→ Choose visually bold marbles, but still test for finish retention.

ESTA’s recent material performance brief reinforced the need for “data-driven natural stone selection” to reduce long-term project risk—particularly in climates prone to moisture and chemical exposure.

Green Marble for Hotel Lobby

FAQ – Popular Questions About Choosing Green Marble

1. Is green marble suitable for outdoor installations?

Yes—if it has low water absorption and proven UV/weather performance.

2. Does green marble stain easily?

Some varieties do; choose stones with chemical resistance and proper sealing behavior.

3. Which green marble works best for countertops?

Dense varieties with low etching sensitivity perform best for work surfaces.

4. Is maintenance different for green marble compared to white marble?

Not significantly, though green varieties often resist surface whitening better.

5. How do I verify if green marble is construction-grade?

Check lab tests: absorption, flexural strength, freeze–thaw, and abrasion performance.

Matching Green Marble to Construction Reality

Selecting green marble is not about choosing the “most beautiful” slab—it is about matching mineral properties to the operational demands of a construction environment. Whether the project faces foot traffic, freeze–thaw cycles, UV exposure, humidity, or chemical abrasion, each variety of green marble responds differently.

By understanding geological origin, block stability, mineral density, and surface behavior—and by evaluating stones through laboratory tests and real project data—builders and architects can choose green marble that remains both visually compelling and structurally reliable.

“Green marble succeeds when its geological structure aligns with its operational environment. The best-performing stones are those that demonstrate predictable behavior across moisture cycles, thermal shifts, and mechanical loads. When selection is based on measurable properties, the stone not only enhances design—it protects the integrity of the project.”

This science-driven mindset ensures every installation is both visually expressive and built to endure.

Feature Product

-

Four Season Grey Natural Marble Slabs and Tiles

Four Season Grey Natural Marble Slabs and TilesThe Charm of Four Season Pink Good size for ...

-

Panda Green White Luxurious Quartzite Stone

Panda Green White Luxurious Quartzite StoneArtistic Conception Like moonlight piercing ...

-

Vivid Brilliant Natural Marble of Prague Green

Vivid Brilliant Natural Marble of Prague GreenHow to pack and load ? 1. Fumigated wooden b...