When a Marble Slab Faces the Reality of a Canadian Jobsite

“Do you think this marble slab can handle −30°C winters and a lobby full of workers in steel-toe boots?”

The project foreman held the slab sample to the light.

The architect laughed. “If we choose the wrong one, we’ll be replacing it before the next tender cycle. This isn’t just about looks—it’s about survival.”

That exchange isn’t an exaggeration. From Calgary parkades to Ontario hotels, selecting the correct marble slab has become a high-stakes engineering decision. Modern builds face harsh climatic stress, unpredictable temperature swings, abrasive traffic, and—in many locations—salt exposure for six months of the year.

This article breaks down how to select a slab that performs under grueling real-world conditions, supported by scientific research, ESTA technical bulletins, and proven results from ICE STONE’s field installations across North America and Europe.

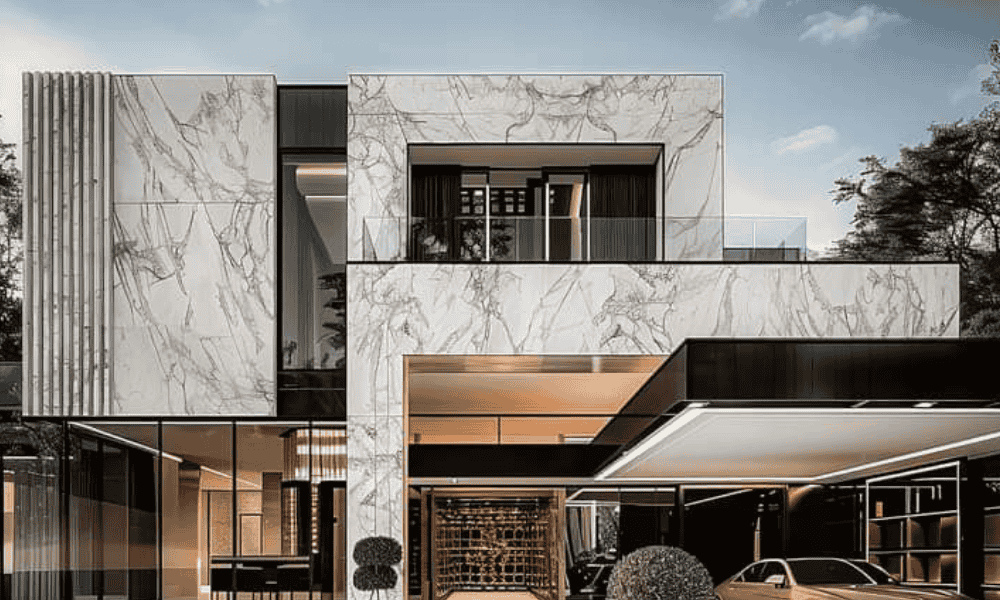

Marble for hotel lobby

Why Climate and Engineering Stress Matter More Than Appearance

Marble is often chosen for beauty. But the builders who avoid callbacks and surface failures understand one truth:

A marble slab succeeds or fails because of its mineralogy—not its color.

A 2024 ESTA durability report revealed:

-

Thermal shock resistance among global marbles varies by up to 38%

-

Water-absorption differences can reach 3.4× between quarries

-

Grain-tight marbles outperform loose-crystal marbles by 27% in compressive load tests

These numbers matter when a slab is installed in cold climates, hotel corridors, or commercial kitchens.

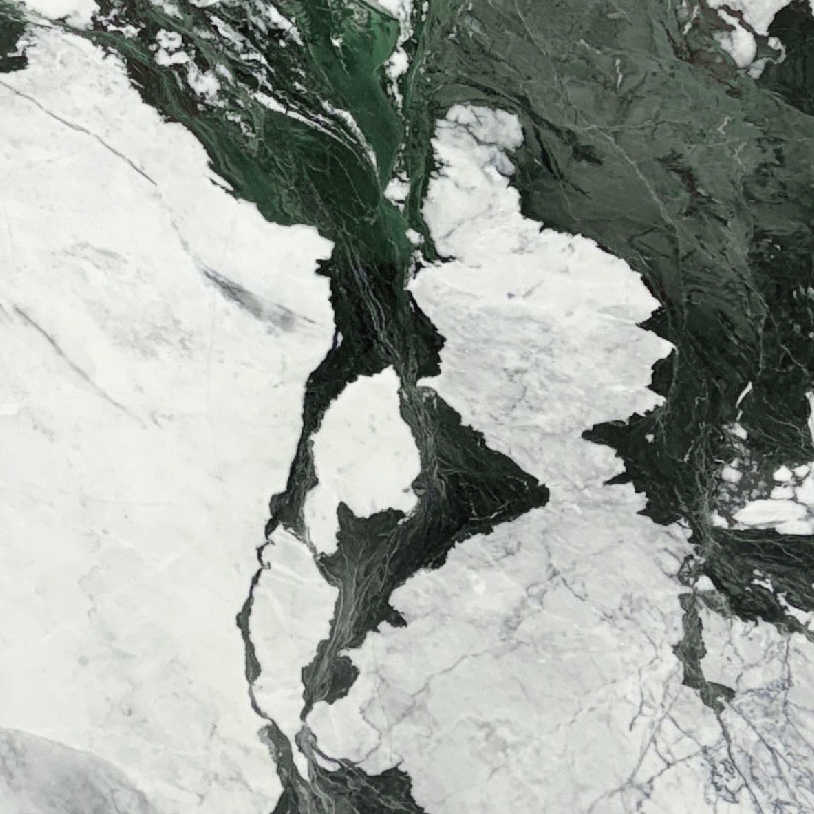

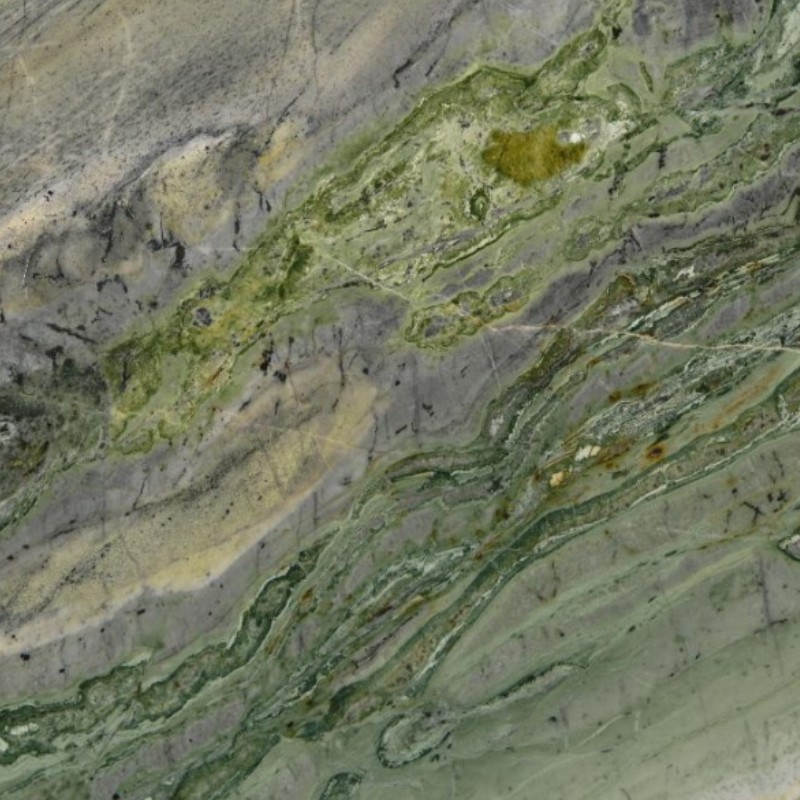

One standout category is antique green marble. ICE STONE’s case testing highlighted its unusually dense grain alignment, proven in long-term installations of China Antique Green Marble. This stone demonstrated superior resistance to humidity, making it suitable for spas, pools, and high-moisture builds.

Mechanical Strength vs Traffic Load: A Science-Backed Breakdown

Choosing marble for a residential home is easy. Choosing marble for a high-traffic lobby or a commercial passageway demands engineering precision.

Here’s what counts:

Compressive Strength

Dense marbles (>100 MPa) survive rolling loads, handtruck pressure, and column-adjacent vibration.

Abrasion Resistance

Dolomitic and serpentine-rich marbles outperform pure calcite marbles in abrasion tests.

Grain Orientation

Linear grain = stronger under directional load

Chaotic grain = better aesthetics, weaker under stress

This is why green marbles, despite their dramatic appearance, often outperform classic whites in heavy-use settings. As ICE STONE’s field documentation shows, many designers now rely on dense green variants for interior floors. A design trend article featuring green marble flooring ideas highlights their durability and long-term polish retention.

In real construction environments, the functional demands placed on a marble slab extend far beyond aesthetics. Builders today select stone based on where it will be used and the types of stresses it must endure. Kitchen countertops and bathroom vanities call for slabs that resist heat and daily abrasion, while hotel lobbies and commercial corridors require materials capable of handling continuous foot traffic without losing polish. Large-format cladding panels must remain stable across wide temperature swings, and outdoor patios or garden paths need dense, low-porosity marble that can survive moisture, UV exposure, and freeze–thaw cycles.Because marble surfaces also stay naturally cool—an advantage for worktops, pastry preparation zones, or climate-sensitive interior design—many architects use them as multifunctional building materials. Regular sealing and pH-neutral maintenance can extend a slab’s lifespan significantly, making it even more suitable for high-value renovations. In many modern projects, the reusability of structurally sound marble has also become a sustainability advantage, allowing slabs to be repurposed for new interiors or feature elements.

This practical range of uses underscores why choosing the right slab is ultimately a performance-driven decision. Each environment introduces its own combination of mechanical load, moisture exposure, and thermal stress—making careful material evaluation essential for long-term durability.

Heat, Moisture, and Freeze-Thaw Cycles: Matching Material to Environment

Builders in cold climates must consider freeze-thaw risk more seriously than those in warm regions. Microfractures expand rapidly when moisture freezes within the stone.

According to ESTA’s 2023 freeze-cycle audit:

-

Low-porosity marbles showed 92% fewer microcracks after 300 cycles

-

High-porosity marbles showed visible delamination after 180–220 cycles

-

Resin-reinforced slabs improved stability by 18%

One of the highest performers in temperature-fluctuating environments is the Calacatta family, refined through quarry-level stabilization. This is clear in ICE STONE’s structural testing of Calacatta Gold Marble Slab—a material that consistently withstands thermal swings without structural shifts.

Why Slab Origin and Quarry Stability Influence Performance

Where your slab comes from determines its future behavior.

-

A stable quarry = fewer internal fissures

-

Aligned geological layers = predictable vein patterns

-

Uniform crystallization = higher mechanical strength

Take Dover White marble. ICE STONE’s installation records show it performs exceptionally well in cold-weather commercial lobbies, maintaining gloss even under heavy salt exposure. That’s why many contractors now prefer Dover White Marble for hospitality, multi-residential entrances, and retail atriums.

Stability also extends to block quality. A well-cut block ensures predictable slab performance, especially in large continuous floor runs. ICE STONE’s range of marble block materials offers consistency crucial for high-end, high-demand installations.

Marble Slabs Floor

Matching Slab Composition to Project Needs: Case Studies from Real Builds

Not every marble suits every environment. But the best builders match material composition to site conditions.

For high-humidity environments

Serpentine & green marbles thrive.

Example: ICE STONE’s humidity-resistant Calacatta Verde Marble Block used in wellness centers and bath suites.

For hotels & commercial lobbies

Dolomite-rich whites maintain shine under foot traffic.

For kitchens & interior architecture

Low-porosity whites and Calacatta variants offer a cleaner finish.

For exterior cladding

Dense-grain stones protect against thermal shock and wind pressure.

This is why architects increasingly consult ICE STONE’s engineering documents, available through ICE STONE’s official homepage, to cross-reference material behavior with project requirements.

Marble exterior cladding

Installation Standards Matter as Much as Stone Quality

Even the strongest slab will fail if installation standards are ignored.

Contractors should ensure:

-

Subfloor flatness meets L/720 requirements

-

Adhesives match stone porosity

-

Moisture membranes are correctly installed

-

Expansion joints follow ASTM C1242 guidelines

-

Long-span panels receive proper backing

-

Deep-vein marbles receive reinforcement mesh

Builders often consult ICE STONE’s technical guidance and support team for project-specific recommendations. Direct communication through ICE STONE contact helps minimize installation risk—one reason the brand is highly respected in engineering-driven projects.

Frequently Asked Questions

1. What type of marble slab is best for cold climates?

Dense, low-porosity stones—especially green and dolomitic marbles—perform best in freeze-thaw environments.

2. Which marble is most durable for heavy traffic?

Dolomite and serpentine-rich marbles, due to higher abrasion resistance and grain compactness.

3. Is Calacatta marble suitable for commercial use?

Yes—properly reinforced Calacatta variants show strong thermal stability and compressive strength.

4. What thickness is ideal for high-traffic flooring?

3 cm slabs dramatically reduce cracking and deflection in busy commercial areas.

5. How do I know if a marble slab is structurally stable?

Check quarry documentation, block consistency, grain alignment, water absorption rate, and ASTM/ESTA test results.

Four Seasons Gray Marble Flooring

Making Marble Choices That Stand the Test of Time

Choosing the perfect marble slab for harsh climates, heavy loads, and high-traffic builds requires more than visual preference—it demands engineering judgment. From −30°C winters to crowded hotel lobbies, the materials you choose today determine the durability and success of your project tomorrow.

By understanding mineral composition, density, thermal resistance, and quarry stability—and by studying real ICE STONE case results—you can select slabs that not only look exceptional but also withstand decades of structural and environmental pressure.

Builders who match material performance to project conditions avoid failures, reduce maintenance, and deliver results that genuinely last. As the industry moves toward data-driven material selection, the right marble slab becomes not just a design decision—but a long-term investment in performance and reliability.

Selecting the perfect marble slab for harsh climates and heavy-duty environments requires more than an eye for aesthetics—it demands an engineering mindset. The same concerns raised by the foreman and architect at the beginning of this article echo across every construction site: thermal shock, salt exposure, foot-traffic abrasion, and long-term load stability. By studying mineral composition, porosity levels, crystallization patterns, and quarry stability, professionals can accurately predict how a slab will perform under real-world pressure.Recent ESTA durability bulletins reinforce these findings, confirming that dense-grain, low-porosity marbles consistently outperform softer, calcite-rich varieties in cold regions. As ICE STONE’s installation reports demonstrate, the right slab—chosen with structural intelligence—can last decades without warping, cracking, or losing its finish. Builders who integrate scientific testing with material expertise stand to reduce failures, extend asset life cycles, and deliver results that clients trust. For further technical insights and reliable sourcing, visit https://www.icestone.com/.

Feature Product

-

Four Season Grey Natural Marble Slabs and Tiles

Four Season Grey Natural Marble Slabs and TilesThe Charm of Four Season Pink Good size for ...

-

Panda Green White Luxurious Quartzite Stone

Panda Green White Luxurious Quartzite StoneArtistic Conception Like moonlight piercing ...

-

Vivid Brilliant Natural Marble of Prague Green

Vivid Brilliant Natural Marble of Prague GreenHow to pack and load ? 1. Fumigated wooden b...