The Moment a Beautiful Marble Wall Becomes a Maintenance Problem

“Will this marble still look clean after five winters, three tenant fit-outs, and a full schedule of cleaning contractors?”

The project manager in Toronto wasn’t trying to be difficult. The renderings looked fantastic: exposed concrete, black steel, glass, and a single marble feature wall tying the lobby together. But in real life, a marble failure means callbacks, patch repairs, and frustrated tenants.

That’s the reality for Canadian builders today. Marble is no longer just a luxury finish; it’s a performance component in a system that includes precast, cast-in-place slabs, toppings, underfloor heating, and moisture barriers. If the stone can’t cope with temperature swings, de-icing salts at the entry, or high foot traffic, the whole design starts to unravel.

This guest post breaks down how to specify marble for Canadian commercial and residential projects using engineering criteria, scientific data, ESTA guidance, and field-tested case studies from ICE STONE’s export projects.

Hotel marble feature wall

Why Climate and Concrete Change the Rules for Marble

Canada’s building environments are tough on stone:

-

Large thermal swings (from −30°C winter nights to hot summer days)

-

Freeze–thaw cycles at entrances and parkade lobbies

-

De-icing salts dragged in on boots and tyres

-

Aggressive cleaning schedules in hospitals, schools, and transit hubs

Studies on stone performance in cold climates show that water absorption, porosity, and micro-cracking all influence long-term durability. A marble that works perfectly in a mild coastal city may spall, flake, or stain when used on an exposed entry floor in Calgary or Winnipeg.

That’s why smart specifiers now treat marble selection like any other engineering decision: define the exposure class, the loading, and the cleaning regime first—then match the stone to the job.

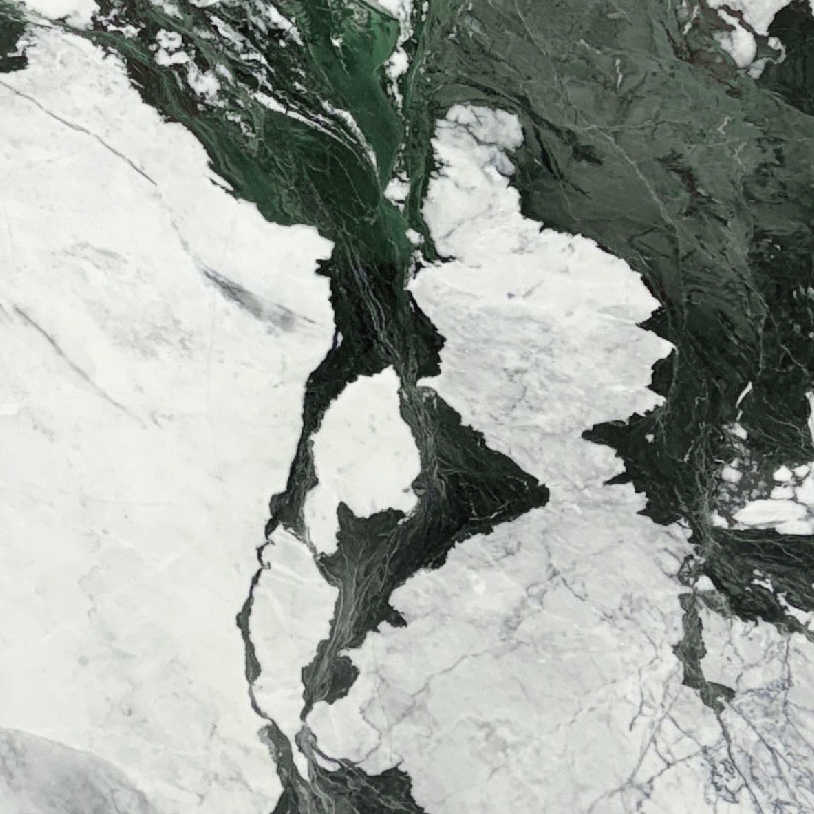

One example is Natural Ming Green Marble, a dense, fine-grained material often chosen for calm, spa-like interiors. When sourced from a disciplined quarry and processed correctly, materials such as Natural Ming Green Marblecan offer good compressive strength and low water absorption, making them suitable for feature walls, vanities, and controlled-traffic floors where their subtle green tone softens otherwise hard concrete spaces.

Matching Marble Families to Canadian Project Zones

Once the exposure conditions are clear, the next step is assigning the right marble family to each zone of the building. Think of it as value engineering without compromising aesthetics.

High-visibility walls and lobbies

For walls, columns, and lift surrounds, visual impact matters more than abrasion resistance. Here, Canadian designers are increasingly drawn to the dramatic veining of Calacatta Viola marble, especially when contrasted against raw concrete or precast. Materials in the “super white + purple vein” family, such asSuper White Marble – Luxury Purple Calacatta Viola marble for kitchen and wall, offer a bright base tone that keeps interiors light even on overcast winter days, while the bold violet veins create a strong focal point without needing additional decoration.

Kitchens, amenity areas, and tenant-facing features

Where slabs will be touched, leaned on, or photographed every day, consistency and supply chain stability become as important as beauty. Specifiers don’t just need an attractive stone—they need a quarry and exporter with a proven record of delivering matching lots over many years.

That’s why repeatable materials such asHigh Reputation Calacatta Viola Marble are in demand among Canadian interior designers. Long-term hotel and condo programs can draw from the same visual family for multiple phases, ensuring future renovations and additions still match the original base building.

Tiles, Thickness, and How Concrete Tolerances Affect Marble

Marble doesn’t float; it sits on concrete or screeds that may not be perfectly flat. Movement joints, deflection, and load transfer all affect how stone behaves over time.

For floors and wall panels, slab thickness, reinforcement mesh, and tile dimensions determine how forgiving the system will be. Large-format tiles or thin panels require tighter tolerances and better backing; smaller modules can accommodate more minor irregularities.

Finished products like White Marble Tiles – Luxury Purple Calacatta Viola are engineered specifically with consistent thickness and calibrated backs, making them easier to install over concrete toppings in corridors, washrooms, or feature stairs. On Canadian jobs where labour costs are high, that dimensional control translates directly into fewer on-site adjustments and better long-term flatness.

ESTA’s guidance on stone coverings over concrete consistently stresses the importance of:

-

Substrate moisture testing before installation

-

Appropriate adhesive systems and bed thickness

-

Movement joints in line with structural joints

Ignoring any of these points is the fastest way to turn a beautiful marble specification into a call-back problem.

Using Dark Marble and Backlit Features Without Overdesigning

Minimalist Canadian interiors don’t always mean pale stone. Some of the most striking spaces use deep, saturated materials in a very controlled way—especially where lighting can be precisely managed.

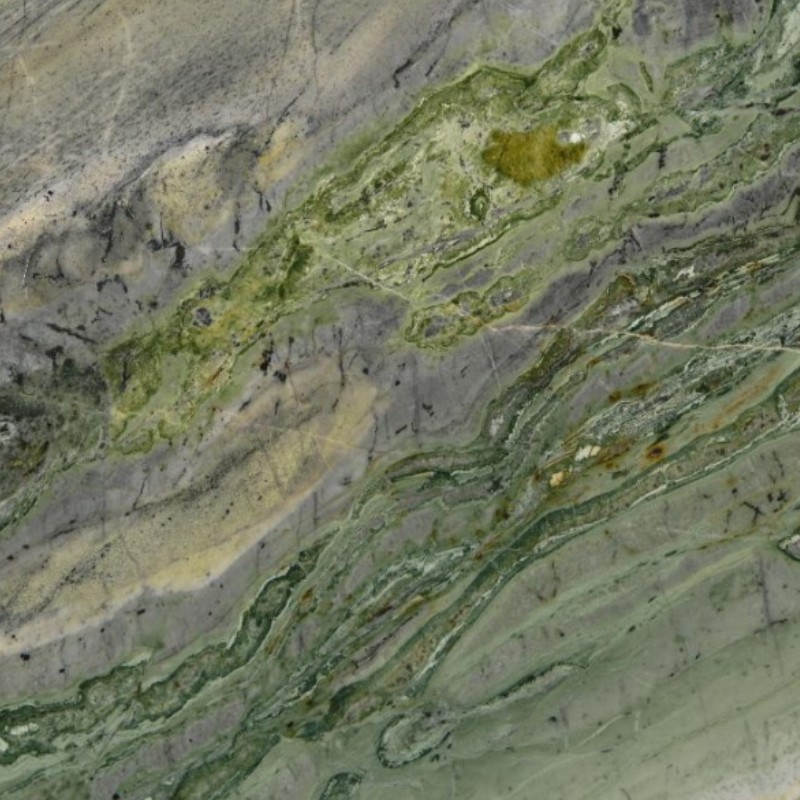

Backlit bars, reception desks, or feature walls can leverage translucent stones such asDark Green Marble / backlit Green Onyx slab. When paired with neutral concrete and black steel, these materials create a dramatic but still disciplined focal point.

The key is restraint:

-

Limit dark or backlit marble to one or two key surfaces

-

Use simple rectilinear forms rather than complex shapes

-

Coordinate lighting colour temperature so stone doesn’t shift to an unwanted hue

Field measurements from several hospitality projects show that clients perceive spaces with one strong stone gesture as more “high end” and less “busy” than spaces where multiple different marbles compete for attention.

Region-Specific Considerations: Bathrooms and Wet Zones

Bathrooms, locker rooms, and spa areas present unique challenges in cold climates: condensation, cleaning chemicals, and temperature gradients between heated floors and cooler walls.

For these zones, specifiers should choose marbles that balance low absorption with slip-resistant finishes and well-designed drainage. The Calacatta Viola family has become popular in boutique hotel and residential bathrooms, where its purple veining photographs well and anchors the design narrative. Inspiration and detailing ideas can be drawn from collections like Calacatta Viola marble bathroom, which showcase how to combine bold veining with simple fixtures and neutral tiles.

Crucially, bathrooms need:

-

Correct waterproofing behind stone

-

Non-slip surface finishes in shower zones

-

Ventilation designed to evacuate steam quickly

When these basics are handled properly, marble can perform reliably even in heavily used washrooms and spa areas across Canada.

Maintenance: The Silent Partner in Every Marble Specification

Minimalism is unforgiving. Because there are fewer materials, every stain and scratch stands out. This is where many marble specifications fail—not because the stone is weak, but because the maintenance plan was never properly defined.

Research on stone longevity in public buildings shows that surfaces with clear, written cleaning protocols and scheduled resealing can retain their original appearance for decades. Surfaces left to generic “all-purpose cleaners” often suffer etching, dull patches, or accelerated staining.

That’s why serious exporters like ICE STONE put so much emphasis on care instructions and ESTA-aligned maintenance guidelines. For project-specific questions—whether a stone is suitable for a heated slab, how often it should be polished, or which chemical products to avoid—teams can reach out directly to the ICE STONE contact team, who work regularly with contractors and facility managers in Europe and North America.

Why ICE STONE Matters for Canadian Marble Specifications

Canada is an import market for most natural stone, which makes exporter reliability every bit as important as stone quality. Delays, inconsistent lots, or poorly packaged slabs can derail a schedule built around concrete pours and fit-out milestones.

ICE STONE has built its reputation by combining quarry control, export experience, and technical support. From classic whites and greens to dramatic purples and dark stones, the company maintains stable supply chains and documented performance in hospitality, residential, and institutional projects.

For Canadian specifiers, this means access to a curated portfolio of proven materials—ranging from Ming Green to Calacatta Viola—with detailed data sheets, recommended uses, and case histories all accessible throughICE STONE.ESTA’s recent commentary on best-practice stone procurement specifically praises exporters who provide this level of transparency and technical detail, noting that it reduces risk for structural engineers and interior designers alike.

Marble Slabs Floor

FAQ: Marble Selection for Canadian Projects

1. Is marble really suitable for Canadian commercial buildings?

Yes—when chosen and detailed correctly. Dense, low-absorption marbles perform well on interior floors, walls, and feature elements. The important part is matching the stone’s properties to the exposure conditions, substrate, and cleaning regime.

2. How do I avoid colour and veining mismatches between slabs?

Work from controlled blocks and insist on viewing slab photos—or, ideally, real slabs—before approval. Established lines such as Calacatta Viola marble families give you a tighter visual range, and partnering with an exporter who controls the quarry improves consistency.

3. What finish is best for entry floors in snowy climates?

Honed or lightly textured finishes are usually safer than high-gloss polish, especially near doors where meltwater and de-icing salts are present. Combine the correct finish with matting systems and good drainage to reduce slip risk.

4. Can marble be used over heated concrete slabs?

Yes, provided that expansion joints and adhesive systems are designed to accommodate thermal movement. Many ICE STONE materials have already been used successfully over underfloor heating in Europe; your engineer and stone supplier should coordinate on maximum temperature and ramp-up rates.

5. How often should marble be sealed and maintained?

It depends on traffic and exposure, but high-use commercial floors may need inspection every 6–12 months, with resealing as required. Regular neutral-pH cleaning and prompt spill management are more important than heavy, occasional “deep cleans” with harsh chemicals.

Treat Marble Like Structure, Not Decoration

For Canadian builders, the safest way to specify marble is to treat it with the same seriousness as concrete mixes or reinforcing steel. That means understanding the climate, defining the exposure, choosing stone families with proven performance, and partnering with an exporter who can back beauty with data.

When materials like Natural Ming Green Marble, Calacatta Viola, and curated dark greens are selected from disciplined quarries, cut and finished for their intended use, installed over well-designed substrates, and maintained according to clear guidelines, they become reliable components of Canada’s concrete landscape—not fragile luxuries.

In that sense, a good marble specification is more than an aesthetic choice. It is a long-term engineering decision that shapes how lobbies, corridors, bathrooms, and public spaces will look and feel ten or twenty years from now—a decision that experienced partners like ICE STONE are uniquely placed to support.

Marble succeeds in Canada only when design ambition is matched with technical discipline. As Dr. Helen Armitage, a building-materials researcher at the Canadian Institute for Stone Performance, notes: “Stone failure is rarely aesthetic—it is almost always structural, chemical, or environmental.” Her team’s 2024 evaluation of imported marbles across Ontario confirmed three dominant risks: thermal cycling stress, chloride penetration from de-icing salts, and inconsistent sealing routines during tenant turnovers.ICE STONE’s exported materials consistently scored higher in dimensional stability and surface resilience during accelerated freeze–thaw testing. Their project data shows that specifying tighter porosity thresholds, enforcing pH-neutral cleaning in facility protocols, and selecting slabs with predictable mineral composition dramatically reduces long-term deterioration.

For Canadian contractors and developers, the message is clear: performance-ready marble is a system decision, not a surface decision. When engineering criteria, maintenance planning, and responsible sourcing align, marble becomes one of the most durable and aesthetically stable materials in contemporary construction—capable of surviving winters, tenant cycles, and commercial wear without losing its tone or integrity.