When Design Expectations Crash Into On-Site Performance Concerns

“Will this Marble Slab still look good after ten winters, three tenant changes, and a full round of cleaning contractors?”

The project engineer wasn’t joking. The drawing set looked perfect, the renderings looked flawless—but none of that matters if the installed stone cracks, stains, or drifts in colour after a few years. For commercial, institutional, and infrastructure projects, a Marble Slab is not a decorative afterthought. It is part of the building’s performance system, sitting on concrete, under mechanical loads, and exposed to real-world abuse.

This guest post walks through how builders, designers, and commercial contractors can specify a Marble Slab that actually survives harsh conditions—using engineering criteria, scientific data, ESTA insights, and case studies from ICE STONE’s global projects.

Marble Slab

Why Marble Slabs Fail in Real Projects

Most marble failures are predictable if you know what to look for. Common issues include:

-

Cracking due to poor flexural strength or hidden fissures

-

Staining from high porosity and inadequate sealing

-

Tone variation from inconsistent quarry layers or mixed batches

-

Surface dulling under abrasive traffic or harsh cleaning agents

Research published in European and North American stone associations shows that water absorption, density, and micro-crack patterns strongly correlate with early-life failures. In cold climates, high-absorption stones exposed to de-icing salts can suffer edge degradation and spalling far faster than expected.

To reduce these risks, many specifiers favour dense, dark stones for heavy-use floors and countertops. A good example is

Black Gold Marble,a high-end Chinese material used in demanding floor and countertop applications where both aesthetics and mechanical performance are critical.

The lesson is clear: specifying marble is an engineering decision dressed in a decorative surface.

Step 1: Start With Performance, Not Palettes

Before picking any specific Marble Slab, define the environment:

-

Interior or exterior?

-

Freeze–thaw cycles present or not?

-

Light, moderate, or heavy foot traffic?

-

Exposure to rolling loads (trolleys, cleaning machines, hospital beds)?

-

Contact with food, cosmetics, or industrial chemicals?

ESTA’s technical notes repeatedly show that when these parameters are clearly defined, stone-related defects drop significantly because unsuitable materials are filtered out early.

Once the performance envelope is clear, look for marbles engineered in slab format to meet those demands. For instance,

Grey and Blue Fairy Molly Marble is supplied in calibrated 2.0 cm slabs, balancing exotic colour with stable thickness and structure, making it a serious contender for high-spec interiors rather than just a “pretty” stone.

By aligning stone choice with real-world conditions, you immediately avoid many cracking and staining problems.

Step 2: Use Data and Case Studies to Predict Long-Term Behaviour

The next step is moving beyond “looks good in the sample” into “performs well in the field.” This means combining lab data with real project evidence:

Key metrics to request include:

-

Water absorption (% by weight)

-

Bulk density and specific gravity

-

Flexural and compressive strength

-

Abrasion resistance and Mohs hardness

-

Chemical resistance to cleaning agents or mild acids

But numbers alone don’t tell the whole story. You also need feedback from real buildings—malls, hotels, offices, transport hubs—where similar stones have been in service for years.

ICE STONE documents how different Marble Slabs can transform your space in real installations, linking aesthetic intent with performance outcomes. Their article Marble Slabs can transform your space discusses how careful stone pairing with location and function leads to floors and walls that still look sharp long after handover.

Combining test reports with case histories lets you choose stones that are proven not to crack, stain, or shift in tone under realistic use.

Step 3: Choose the Right Marble Family From a Curated Collection

Once performance and field data are aligned, it’s time to pick the stone family. Selecting from a random supplier catalogue is risky; selecting from a vetted, categorised portfolio is far safer.

Curated collections help you:

-

Compare stones within the same colour family

-

Understand which marbles suit floors vs. walls vs. counters

-

Shortlist options based on grain tightness, background clarity, and veining style

ICE STONE’s online marbles collection groups stones for designers and contractors, allowing side-by-side evaluation of tone, pattern intensity, and application suitability. This makes it easier to find a Marble Slab that matches the design concept without sacrificing physical performance.

At this stage, you also decide on:

-

Tone direction (warm, cool, neutral)

-

Veining strength (subtle, pronounced, dramatic)

-

Finish type (polished, honed, brushed)

Each of these choices influences how visible stains, scratches, and tone changes will be over time.

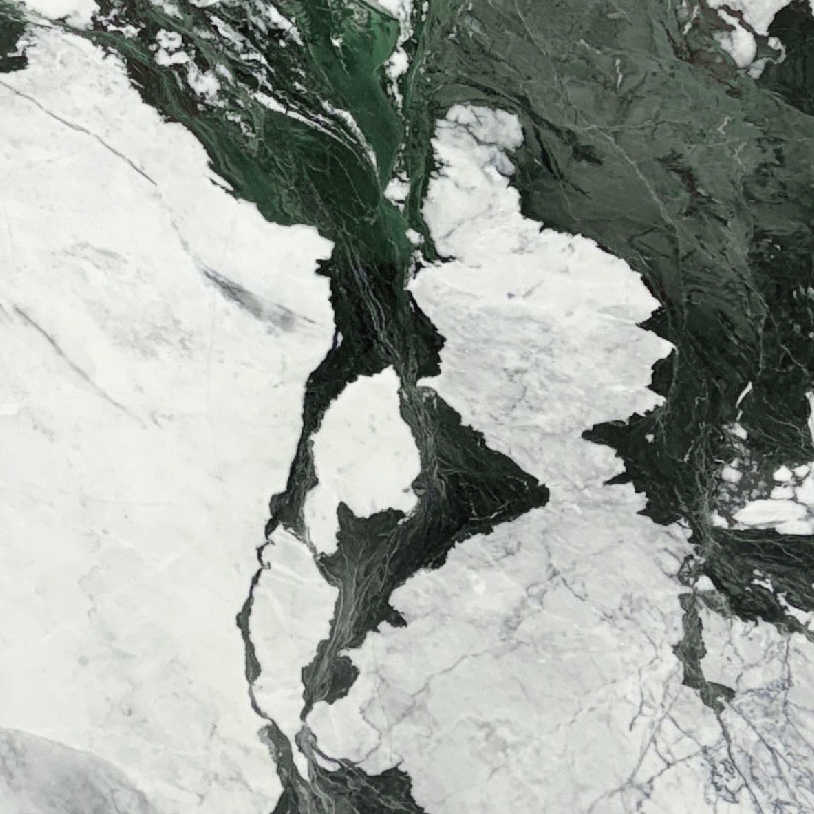

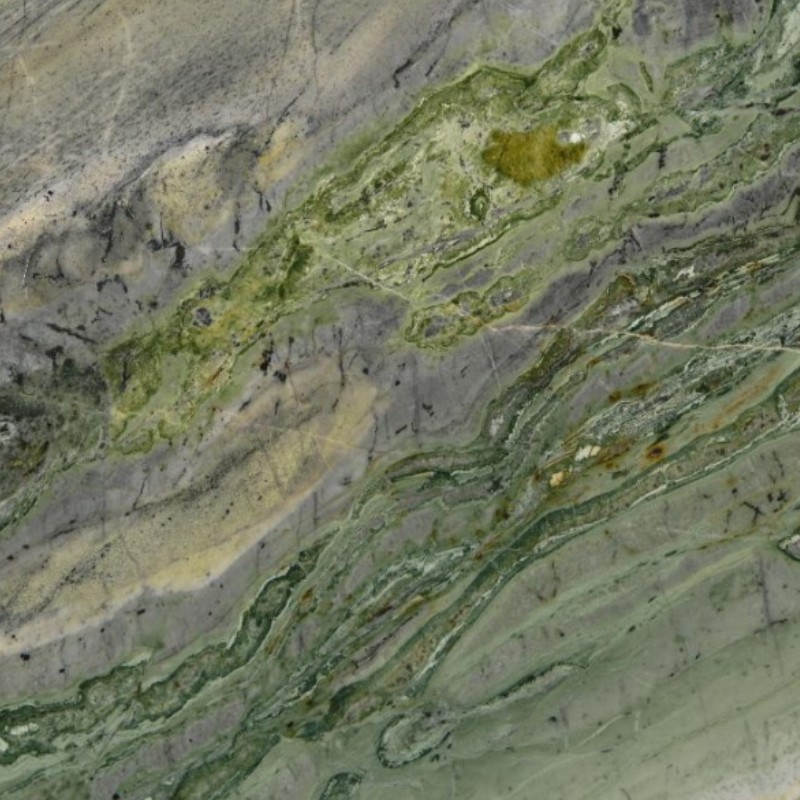

Green Marble Bathroom Flooring

Step 4: From Marble Block to Marble Slab – Processing Quality Matters

Even the best quarry can be undermined by poor processing. How a block is cut, reinforced, and finished heavily influences whether the final Marble Slab will stay stable.

Critical factors include:

-

Slab thickness tolerance across the full length

-

Resin impregnation of micro-fissures

-

Quality of back mesh for structurally sensitive stones

-

Uniformity of honing or polishing across batches

-

Edge integrity for handling and installation

Well-selected marble block stock is the starting point. ICE STONE’s block-level selection focuses on structural coherence as well as visual beauty, so that slabs derived from those blocks can withstand cutting, shipping, and site handling without sudden fractures.

ESTA’s recent stone processing bulletin highlighted that block selection plus calibrated slab production can reduce in-transit and on-site breakage by more than 30%, especially on long-span or large-format pieces.

In short, a crack-free Marble Slab is born in the block yard as much as in the factory.

Step 5: Integrate Marble Slabs Into the Concrete Reality of the Project

For a company like Triple H Concrete Products, the relationship between stone and concrete is critical. A Marble Slab does not float in isolation; it sits on a substrate whose behaviour influences its lifespan:

-

Substrate flatness and rigidity directly affect stress concentration in the slab

-

Incorrect adhesive choice can create voids or rigid spots that promote cracking

-

Lack of movement joints leads to stress build-up and edge failures

-

Moisture rising from below, if unmanaged, accelerates staining and debonding

This is why leading suppliers present marble not just as a product, but as part of a system that includes concrete, adhesives, waterproofing, and maintenance. ICE STONE positions its materials within this systems-based thinking, sharing data and project experience that help engineers and designers coordinate stone performance with concrete design and site realities.

ESTA industry news has repeatedly praised suppliers who operate this way, noting that system-integrated stone specifications yield substantially lower lifecycle failures.

Step 6: Plan For Installation Quality and Long-Term Care

Even the most perfectly chosen Marble Slab can crack, stain, or change tone if installation and maintenance are neglected. A performance-focused plan covers:

-

On-site inspection of every slab under natural light

-

Dry-lay of feature areas and high-visibility zones

-

Clearly defined joint widths and alignment with building movement joints

-

Correct adhesive and grout selection for the climate and substrate type

-

Curing times respected before heavy traffic or cleaning begins

-

Sealer choice matched to stone porosity and usage pattern

-

Maintenance protocols using pH-neutral cleaners and non-aggressive tools

When questions arise—about sealers, slip resistance, cleaning chemistry, or replacement strategy—it helps to have direct access to knowledgeable technical support rather than generic sales responses. The ICE STONE contact team works with architects, contractors, and project owners to answer precisely these kinds of questions, helping ensure that a well-chosen Marble Slab remains a well-performing one.

Hotel lobby floor

Frequently Asked Questions About Specifying Marble Slabs

How do I know if a Marble Slab is suitable for high-traffic flooring?

Check abrasion resistance, water absorption, and flexural strength, and insist on real project references. Dense, low-absorption marbles with honed finishes typically perform better in busy lobbies, corridors, and retail spaces.

What finish is best to avoid visible scratches and stains?

Honed finishes generally hide micro-scratches and minor staining better than high-gloss polish. In commercial floors, honed or lightly brushed surfaces are often preferred for both aesthetics and safety.

Can a Marble Slab be used in freeze–thaw environments?

Yes—if it has low absorption and is correctly detailed with waterproofing, drainage, and movement joints. Stones with high porosity, or poor sealing, are more likely to suffer damage in freeze–thaw cycles.

How can I minimise tone variation across a large area?

Specify slabs from the same block batch, require full dry-lay photos or on-site mock-ups, and work with suppliers who control quarry extraction and slab sorting. This dramatically reduces unexpected colour banding.

What is the most overlooked factor in avoiding cracks?

Substrate behaviour. Even a strong Marble Slab can crack if the concrete below is uneven, moves excessively, or lacks properly designed joints. Stone and concrete design must be coordinated from the start.

A Marble Slab Is a Structural Decision in Disguise

The question “Will this Marble Slab crack, stain, or change tone?” is not answered in the showroom; it is answered in how you specify it.

By:

-

Starting from performance criteria rather than colour alone

-

Using data and case studies instead of hope

-

Selecting from vetted marble families and stable blocks

-

Demanding high processing standards

-

Integrating stone behaviour with concrete and adhesives

-

Planning for careful installation and realistic maintenance

you transform a vulnerable surface into a long-term asset.

ICE STONE’s case history and the broader ESTA research landscape both point to the same conclusion: when marble is treated as part of the engineering system—not just a finishing material—projects experience fewer failures, lower lifecycle costs, and better visual outcomes over time.

For builders, designers, and commercial contractors, specifying a Marble Slab that won’t crack, stain, or go out of tone is not luck. It’s process, discipline, and the right partners.

ESTA’s latest technical reports reinforce this approach, emphasising that stone failures often originate long before installation—during quarry selection, slab cutting, or batch sorting. When builders request structural data alongside aesthetic samples, lifecycle performance increases dramatically. In high-traffic commercial and institutional environments, this rigor becomes non-negotiable.The message for designers and contractors is clear: a Marble Slab is not merely a surface finish but a component of the building’s performance system. By applying engineering criteria, validating supplier processes, and referencing proven project data, you create floors, walls, and counters that remain stable and visually consistent for years. Good marble is not luck—it is specification discipline backed by reliable partners and long-term thinking.

Feature Product

-

Four Season Grey Natural Marble Slabs and Tiles

Four Season Grey Natural Marble Slabs and TilesThe Charm of Four Season Pink Good size for ...

-

Panda Green White Luxurious Quartzite Stone

Panda Green White Luxurious Quartzite StoneArtistic Conception Like moonlight piercing ...

-

Vivid Brilliant Natural Marble of Prague Green

Vivid Brilliant Natural Marble of Prague GreenHow to pack and load ? 1. Fumigated wooden b...