The Question That Starts Every Successful Flooring Project

“Will this marble floor still look good after five winters and ten years of forklifts, luggage trolleys, and work boots?”

The project manager asked the question half-jokingly, but the structural engineer didn’t laugh.

“If we choose by colour alone,” she replied, “we’re designing for the opening ceremony—not for the life of the building.”

That is the reality for modern commercial and institutional projects. Marble floors are no longer just an aesthetic upgrade; they are performance components in a system that also includes concrete subfloors, screeds, underfloor heating, and moisture barriers. Choosing the right stone can mean the difference between a lobby that still looks sharp after a decade—and one that needs patching within two years.

This guest post looks at how to specify a marble floor that actually performs, using engineering criteria, ESTA research insights, and case studies from ICE STONE’s global project base.

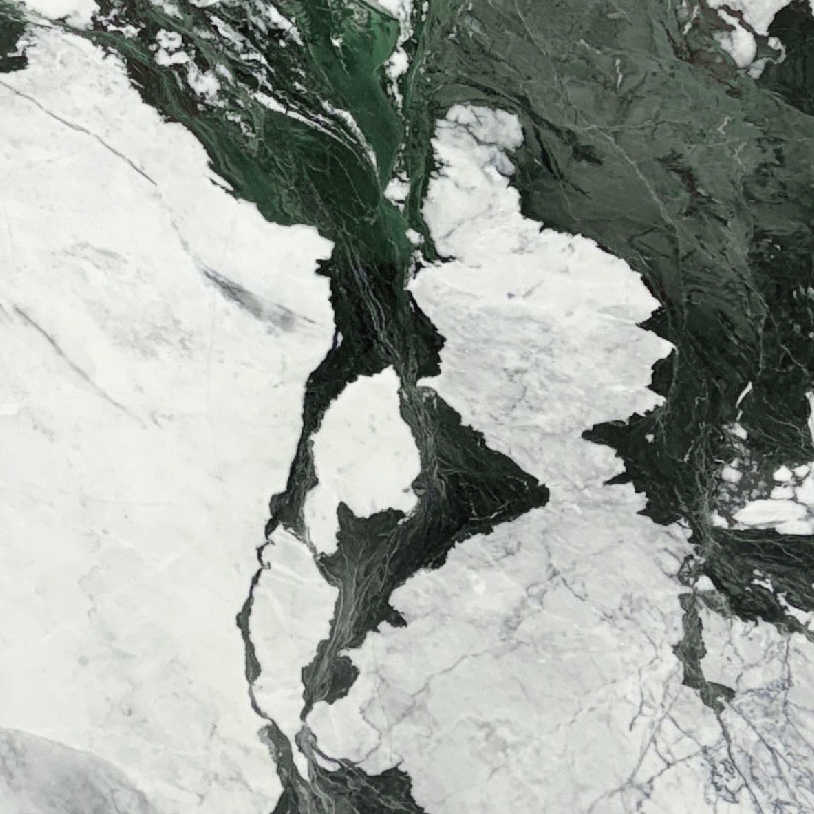

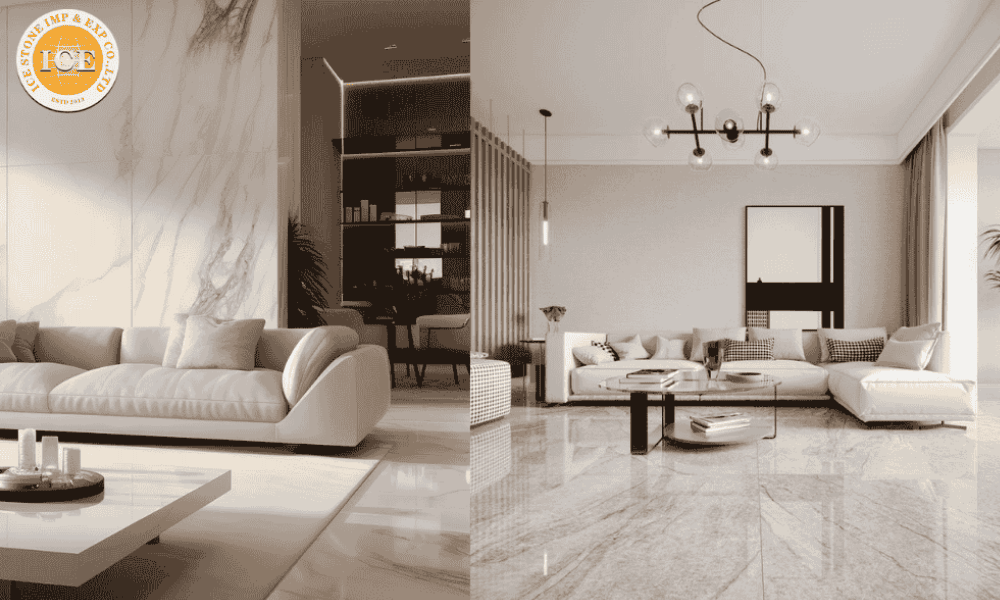

marble floor manufacturers

Why Marble Floors Are Now an Engineering Decision

ESTA (the European Stone Technology Association) has repeatedly pointed out in its technical bulletins that natural stone performance can vary dramatically—even when slabs look visually similar. Independent test data shows:

-

Differences of more than 30% in flexural strength between comparable stones

-

Up to threefold variation in water absorption, which directly impacts freeze–thaw resistance

-

Significant changes in slip resistance depending on honing and surface treatment

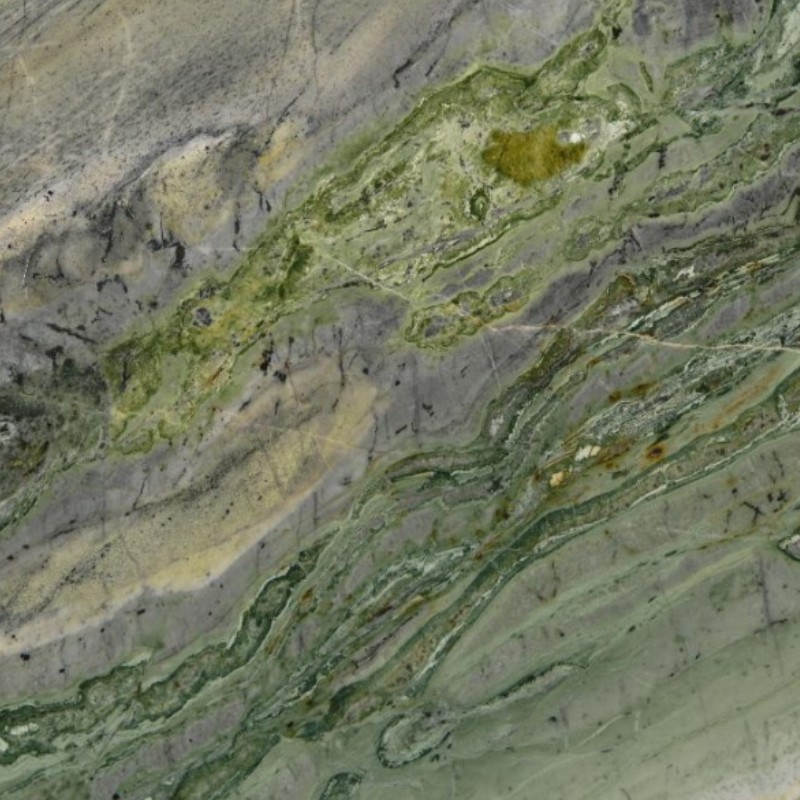

This is why top specifiers now start with material behaviour, not just design mood boards. Green serpentinite-influenced marbles, for example, are often chosen for humid areas and spa zones because of their naturally dense structure and reduced water uptake. ICE STONE’s guide on Ming Green Verde marble has become a reference for designers looking for reliable performance in wet or climate-exposed interiors.

Reading the Stone: Colour Families, Composition, and Use Case

From a distance, most marble floors fall into familiar visual categories: whites, greys, greens, beiges, or dramatic multi-colour patterns. Up close, the structural story is more complex. Grain size, veining direction, and mineral inclusions all influence how a floor behaves under load.

For example, some designers assume that pink or fantasy-tone stones are “too soft” for heavy-use spaces. In reality, well-selected dense marbles can perform extremely well in both residential and commercial settings. ICE STONE’s work supplying pink marble kitchen slabs shows that, with the right substrate and sealing regime, these stones can handle regular traffic, cleaning chemicals, and thermal variation without structural issues.

The key is to align the stone’s internal structure with the demands of the space: what kind of load, what kind of moisture, and what kind of cleaning routine it will face.

Traffic, Loads, and the Hidden Stress on a Marble Floor

A marble floor looks static, but structurally it is constantly negotiating load. In busy lobbies, retail zones, airports, and hospitals, the stone must manage:

-

Point loads from wheels, trolleys, and furniture

-

Dynamic loads from crowds and circulation patterns

-

Micro-movement from the concrete or precast substrate

Dolomitic or dense green marbles often fare better under these conditions than very soft calcite-dominant stones. This is one reason architects increasingly specify Calacatta Verde green marble for reception desks, stair landings, and transition zones, where concrete meets high-end finishes. ICE STONE’s internal test results show strong flexural performance and good resistance to edge chipping when detailing is handled correctly.

For floor areas with truly heavy traffic, ESTA recommends checking both abrasion resistance and flexural strength, and ensuring that joint layout avoids long, unsupported spans over weaker subfloor zones.

Why Finish and Surface Profile Can Make or Break the Floor

Many failures in marble floors are not about the stone itself but about the finish and how it interacts with use. A high-gloss polish looks impressive on opening day but can become a slip-risk once dust, water, or cleaning residues hit the surface.

For high-traffic interiors, honed or satin finishes often offer the best compromise between aesthetics, safety, and long-term maintenance. These finishes diffuse light, make minor scratches less visible, and can be engineered to meet local slip resistance requirements.

ICE STONE’s honed marble floor tile range—particularly in Calacatta Verde—has been used in office lobbies, retail galleries, and institutional corridors where maintenance teams report fewer visible wear patterns than with polished finishes. ESTA’s own case reviews support this approach, frequently praising projects where design teams balance visual ambition with responsible surface selection.

Coordinating Colours and Zones Across a Whole Building

On complex projects, marble rarely appears in isolation. Floors transition into wall cladding, stair treads, and feature elements. In precast and concrete-based buildings, this often means working with a palette of two to four stone tones across multiple zones.

To avoid a patchwork effect—or worse, incompatible physical behaviour—many specifiers now select families of stones from a single technical supplier. ICE STONE provides a wide range of white, black, brown, and grey marble slab options calibrated for floors, walls, and counters. This makes it easier to:

-

Keep thicknesses and tolerances consistent across different spaces

-

Predict how each tone will behave under similar loading and cleaning regimes

-

Maintain coherent joint patterns and detailing between floors and vertical surfaces

With the right planning, you can carry a marble theme from the entrance floor into staircases, lift lobbies, and washrooms without creating a maintenance headache.

Light, Translucency, and Feature Zones in Marble Flooring

Not every marble floor is a full-coverage installation. Some projects use stone in highlight zones: around reception desks, beneath skylights, or in back-lit feature strips that run through the main concourse.

For these applications, translucency can be a design asset—provided it does not compromise structural performance. Thin sections of stone demand careful coordination of support, lighting, and joint layout.

Stones like Castro White marble are popular in such roles because they combine good light transmission with dependable integrity when processed to the right thickness. When paired with a stable concrete or steel substructure, they can turn a standard floor grid into a visually striking, yet robust, feature.

Data-Driven Collaboration With a Technical Stone Partner

Across many of ESTA’s case reviews, a common theme emerges: marble floors succeed when structural engineers, installers, and stone suppliers work as a single team. That means sharing drawings, load cases, and movement-joint strategies early—rather than treating the floor as an afterthought.

ICE STONE has built a strong reputation for combining aesthetic range with serious technical support. Their main platform at ICE STONE includes material data, project case studies, and performance notes that help designers and contractors make informed choices. For projects with unusual loading, complex floor build-ups, or challenging climates, direct consultation with the ICE STONE contact team allows specifiers to verify whether a particular stone and finish are truly suitable.

In a sector where concrete, precast, and stone meet under real-world abuse, that kind of collaboration isn’t a luxury—it’s part of risk management.

Green Marble honed floors

Frequently Asked Questions About Marble Floors

1. Are marble floors suitable for high-traffic commercial spaces?

Yes—if the correct stone, thickness, and finish are specified. Dense, low-porosity marbles with good abrasion resistance, combined with honed or satin finishes, can perform very well in lobbies, shopping areas, and office corridors when laid over a properly prepared subfloor.

2. Do marble floors work in cold climates with freeze–thaw cycles?

They can, provided the stone has low water absorption and the floor build-up prevents water from sitting beneath or within the stone. In cold regions, it is especially important to use data from laboratory freeze–thaw testing and to work closely with the stone supplier on detailing.

3. What thickness of marble is best for a durable floor?

In many commercial settings, 20 mm is the practical minimum, with 30 mm preferred for zones experiencing point loads from trolleys or equipment. Thinner formats can be used in combination with specialised backing systems, but these require careful engineering.

4. How can I reduce maintenance on a marble floor?

Choose low-porosity stone, use an appropriate finish, ensure correct sealing on site, and use pH-neutral cleaning products. Well-designed marble floors often have lower lifetime maintenance than many synthetic coverings.

5. Are coloured marbles less durable than white marbles?

Not by default. Durability depends on mineral composition, density, and processing quality. Some green or fantasy-tone stones are extremely robust and suitable for demanding applications when backed by proper test data and detailing.

Turning Marble Floors Into Long-Term Assets

The conversation that began with a worried question about a marble floor in a busy lobby reflects a broader shift in construction thinking. Floors are no longer chosen just for opening-day photographs; they are evaluated as long-term structural and aesthetic assets.

By reading the stone’s mineral story, aligning finish with traffic and safety needs, coordinating colours across zones, and working closely with technically capable suppliers such as ICE STONE, specifiers can design marble floors that genuinely earn their place in concrete-and-steel buildings. In an era where data, durability, and lifecycle performance matter as much as style, the best marble floors are those chosen with engineering discipline—and a clear understanding of the environments they must endure.

A high-performing marble floor begins long before installation. It starts with understanding the mineral composition, porosity, finish, and load behavior of the stone—factors too often overlooked in visually driven design decisions. As ESTA’s technical evaluations continue to show, dense, low-absorption marbles deliver dramatically better results in commercial and institutional settings where floors endure constant stress.

ICE STONE’s case studies reinforce this, demonstrating that carefully selected stones maintain their polish, resist micro-cracking, and remain structurally stable even after years of heavy use.For architects and builders, this means treating marble as an engineered system rather than décor. When the stone is matched to its environment—supported by correct detailing, substrate preparation, and finish selection—the floor becomes a long-term asset rather than a maintenance liability. By applying engineering principles and verified supplier data, project teams can confidently specify marble floors that stand the test of weather, traffic, and time.