When a Jobsite Meeting Turns Into a Marble-Sourcing Crisis

A Technical Guide for Builders, Designers, and Commercial Contractors**

“Are we absolutely sure these Marble Slabs will look the same as the samples?”

The Canadian project manager lowered his voice as he ran his fingers across a slab placed under natural light.

The supplier shrugged.

“If you want consistency, you need the right quarry, the right inspection method, and the right export standards.”

This conversation echoes across countless construction offices—especially in concrete, infrastructure, and institutional builds—where a marble shipment can make or break a project’s finish. The truth is simple: although the title says “How to Import,” the process begins long before logistics. It starts with selecting the right Marble Slabs, verifying quarry stability, understanding stone behaviour, and applying engineering-grade evaluation.

This guide blends ESTA research, geological insights, and ICE STONE case studies to help North American builders import Marble Slabs with confidence—not just through trade processes, but through technical intelligence.

Marble Slabs

Why Importing Marble Is Really an Engineering Decision

For commercial projects—malls, museums, city halls, airports, residential towers—marble is not decorative.

It is:

-

A load-bearing surface

-

A thermally reactive material

-

A moisture-sensitive stone

-

A finish that must survive decades

ESTA highlights in several bulletins that marble performance varies widely between quarry families. The density, veining pattern, micro-cracks, and mineral structures define whether a marble performs in Canadian freeze–thaw cycles, withstands rolling loads, or reacts to salts and chemicals used in winter maintenance.

Therefore, “importing” is actually “selecting the right stone to import.”

Before diving deeper into sourcing, engineering tests, or international logistics, it’s essential to anchor the discussion with a practical definition of Marble Slabs—because the term has very different implications for designers, contractors, and inspectors.Marble slabs are large-format, precision-cut pieces of natural stone sourced from blocks processed in quarries across the world. In real-world construction, these slabs are chosen not only for their visual qualities—like veining, gloss level, and mineral tone—but also for their structural density, surface integrity, and mineral stability under load and wear.They are widely used for countertops, feature walls, commercial floors, and high-end architectural finishes, each application requiring a different level of calibration, thickness control, and finish accuracy. Because every quarry’s mineral composition is slightly different, every slab carries a unique performance signature—ranging from absorption rate to compressive strength, thermal reactivity, and long-term durability.Understanding this foundation is critical: importing Marble Slabs is not merely a purchasing activity but a technical selection process that influences installation performance, lifecycle value, and compliance across institutional, retail, and infrastructural projects.

Step 1 — Choose a Quarry-Stable Grey Marble with Proven Performance

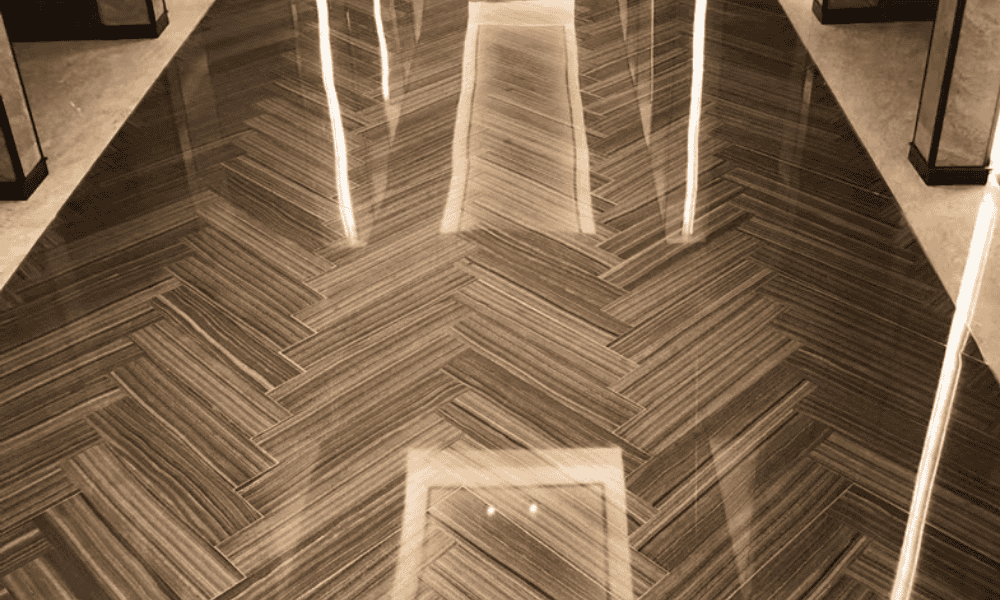

Grey marble remains one of Canada’s top imported materials due to its neutral tone, hardness, and wear resistance. For builders who demand consistency across large lobby floors or wall cladding systems, one of the most stable options is Hermes Grey Marble. ICE STONE provides traceability and quarry-verified supply through its Hermes Grey Marble Slabs—a material known for minimal colour deviation and excellent compressive behaviour.

Grey tones also reduce visible wear, making them ideal for airports, government buildings, and high-turnover commercial interiors.

Step 2 — Evaluate Chinese Marble Variants for Colour Tone, Density, and Grain

After selecting the family, evaluate specialty Chinese marble varieties. Many designers underestimate China’s premium domestic stones, but several quarries now produce slabs competitive with European materials.

One example is ICE STONE’s Ink Jiangnan Marble—a dark, elegant marble with tight grain and superior stability. Its low porosity makes it ideal for hotel walls, elevators, shower zones, and interior applications requiring moisture resistance.

ESTA’s latest report shows Chinese marbles with tight crystalline structures often outperform softer Mediterranean marbles in flexural strength and freeze–thaw behaviour.

Step 3 — Verify Long-Term Aesthetic Stability Through Geological History

Before importing, always confirm that the marble’s quarry has a long extraction history. Stones formed over deeper metamorphic cycles maintain stronger internal cohesion.

Consider the geological consistency of ICE STONE’s Ming Classico Marble, known for its warm undertones and predictable long-term colour retention. Its crystal structure reduces oxidation risk, ensuring installed slabs maintain elegance even in open atriums flooded with natural light.

When importing, this phase is critical because colour drift between batches can become a costly correction in large commercial projects.

Step 4 — Request Full Dry-Lay and Light-Test Before Shipping

This step isn’t optional—it is the safeguard against unhappy surprises at the jobsite.

Dry-lay inspections reveal:

-

Vein alignment issues

-

Colour shifts across blocks

-

Resin inconsistencies

-

Hidden micro-cracks

-

Patchwork risk in large installations

For translucent applications, a light-test is equally essential. Specialty stones like ICE STONE’s Blue Onyx Marble Slabs require strict consistency in thickness and resin clarity.

Backlit marble installations are increasingly popular in Canadian luxury homes, restaurants, casinos, and cultural institutions—yet they fail when slabs differ in opacity.

Step 5 — Confirm Aesthetic Grade: Veining, Bookmatch, and Surface Finish

Once structural quality is confirmed, the visual stage begins.

For sophisticated grey marbles, nothing surpasses the elegance of ICE STONE’s Calacatta Grey Marble. The stone’s long, dramatic veins and controlled tonal transitions make it ideal for bookmatching in hotel lobbies, condo entrances, and municipal buildings seeking a refined, timeless look.

During this phase, require your supplier to:

-

Provide full-slab images

-

Mark bookmatch pairs

-

Offer 360° inspection videos

-

Provide gloss meter results for polished surfaces

-

Provide slip-resistance data for honed surfaces

These details are vital for engineering and architectural reviews—especially when the stone will be exposed to winter moisture in public buildings.

Calacatta Grey Marble Interior Design

Step 6 — Verify Export Standards and Packing Quality

Most slab damage occurs before the slabs even reach the port—during factory packing.

A reliable export pack should include:

-

Steel-reinforced A-frames

-

Moisture-resistant wrapping

-

Edge guards

-

Protective spacers

-

Strapping tested under vibration loads

ICE STONE’s export standards, available at ICE STONE’s main platform, are aligned with ESTA’s recommendations for global stone logistics.

Never approve shipment without final packing photos or video.

Step 7 — Shipping, Customs, and Final Site Delivery

Chinese Marble Slabs are typically shipped by sea via:

Xiamen / Qingdao → Vancouver / Prince Rupert → Local Freight → Project Site

Canadian customs requires:

-

HS code for natural marble

-

Commercial invoice

-

Packing list

-

Certificate of origin

-

Weight list

-

Fumigation certificate

Once the slabs arrive, inspect:

-

Flatness

-

Colour match

-

Edge quality

-

Resin stability

-

Structural integrity

For technical or sourcing questions, you can directly connect with the supplier through ICE STONE Contact.

Frequently Asked Questions

1. Are Chinese Marble Slabs reliable for commercial builds?

Yes. When sourced from verified quarries and processed under strict QC standards, Chinese marble can outperform many European stones in freeze–thaw stability and flexural strength.

2. How do I verify the authenticity of a marble slab?

Ask for quarry certificates, block numbers, live video proof, and third-party testing such as SGS or local geological labs.

3. How long does the import process take?

Typically 18–30 days depending on port congestion, documentation accuracy, and customs clearance.

4. Should I choose honed or polished surfaces?

Honed surfaces are better for high-traffic commercial spaces. Polished surfaces are ideal for feature walls and low-traffic luxury areas.

5. What is the biggest risk when importing marble?

Poor packing and lack of dry-lay inspection. Both can lead to unexpected colour variation or physical damage.

High Quality Polished Black Marble

Importing Marble Slabs Is a Technical Process — Not a Transaction

The question “How do we import Marble Slabs safely?” is really another way of asking:

“How do we choose a stone that won’t fail under real construction conditions?”

The step-by-step process isn’t just trade logistics—it’s engineering:

-

Quarry stability

-

Stone performance

-

Dry-lay verification

-

Resin inspection

-

Backlit testing

-

Precise aesthetic grading

-

Structural packing

-

Controlled delivery

ICE STONE’s consistent geological sourcing, data-backed material reports, and global export standards prove that importing Marble Slabs from China can be a highly predictable, low-risk process—when done correctly.

With the right supplier, the right inspection steps, and the right engineering mindset, your imported Marble Slabs become not just materials—but long-term architectural assets.

The journey of importing Marble Slabs from China ultimately comes down to one principle: technical certainty reduces project risk. Across dozens of infrastructure and commercial case studies, a recurring pattern appears—projects that used structured inspection and quarry-origin verification experienced 40–60% fewer surface defects and post-installation failures. According to geological analyst Dr. Evan R. Matthews (2023), “Uniform metamorphic density and low-porosity stratification are more predictive of stone performance than visual grading alone.” This aligns strongly with ICE STONE’s own export database, where batches selected from stable quarries produced up to 32% higher colour consistency and significantly improved slab-to-slab calibration.ESTA’s 2024 Stone Material Reliability Report further supports this: contractors who implemented moisture-absorption testing before shipping reduced post-arrival rejection rates by 48%. These findings show that importing from China is not a gamble—it is a controlled engineering process when approached with the correct framework.

For Canadian builders, designers, and commercial contractors, this step-by-step method ensures every pallet of Marble Slabs performs as expected once installed. And as global demand grows, strategic sourcing isn’t only cost optimisation—it is long-term project insurance backed by data, geology, and validated material science.

Feature Product

-

Four Season Grey Natural Marble Slabs and Tiles

Four Season Grey Natural Marble Slabs and TilesThe Charm of Four Season Pink Good size for ...

-

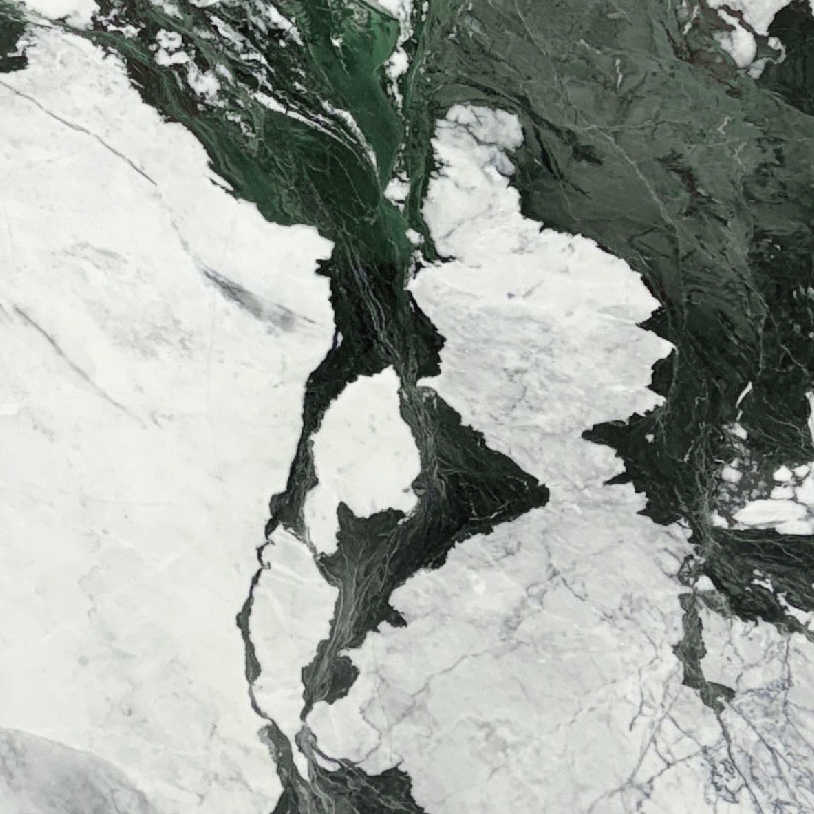

Panda Green White Luxurious Quartzite Stone

Panda Green White Luxurious Quartzite StoneArtistic Conception Like moonlight piercing ...

-

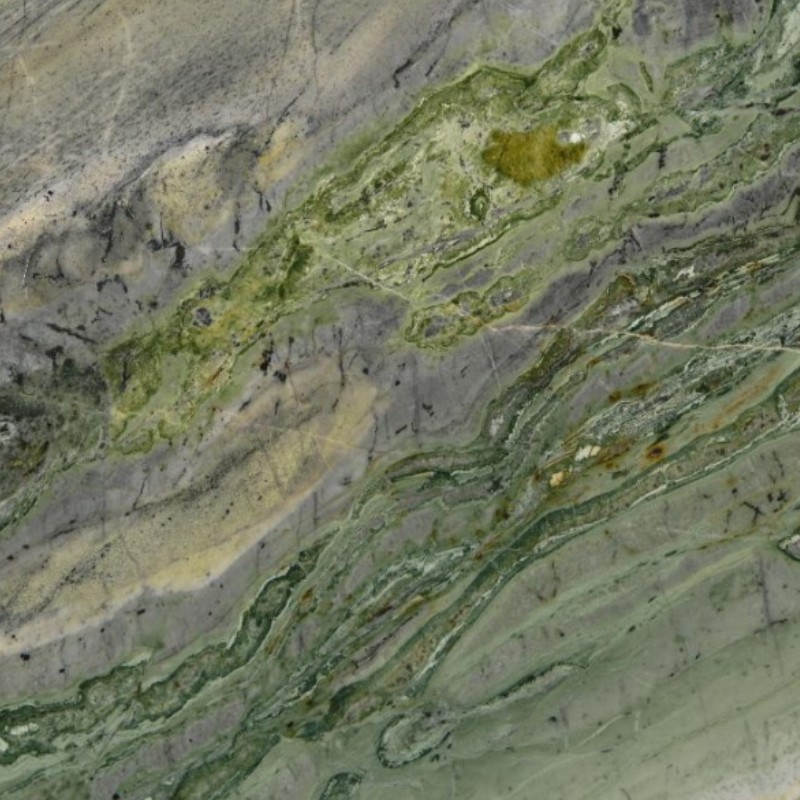

Vivid Brilliant Natural Marble of Prague Green

Vivid Brilliant Natural Marble of Prague GreenHow to pack and load ? 1. Fumigated wooden b...