The Moment the Engineer Asked the Hard Question

“Will this stair still be safe and presentable after ten years of schoolkids, trolleys, and cleaning crews?”

A project engineer asked that while standing in a concrete shell, looking at a mock-up of a grand marble staircase. The renderings looked spectacular. But in real public buildings, stairs are not just photo opportunities – they are safety-critical infrastructure. A marble slab on a staircase has to cope with impact, abrasion, moisture, and thousands of footfalls every day.

This guest post looks at how to design durable marble staircases in public buildings using engineering logic, real-world case experience, and export know-how from icestone’s projects worldwide.

marble staircase

Why Marble Staircases in Public Buildings Fail (and How to Avoid It)

Stair failures with stone almost never happen “because marble is weak.” They happen because:

-

The wrong stone or finish was chosen for a high-traffic zone

-

The marble slab dimensions and supports don’t match the load path

-

Slip resistance and cleaning regimes were an afterthought

-

Expansion, movement joints, and substrate conditions were ignored

Industry investigations in Europe and North America consistently show that the riskiest combination is: highly polished stone, heavy traffic, poor drainage, and aggressive cleaning chemicals. Public buildings – schools, hospitals, transport hubs, civic centres – often tick all four boxes.

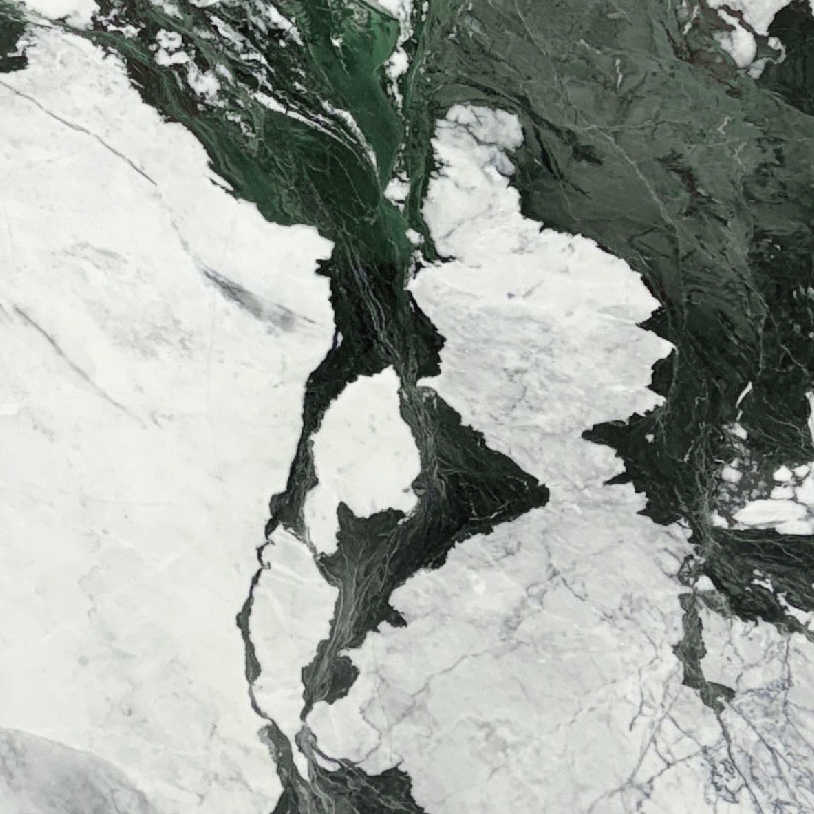

The starting point is to choose stones with predictable performance and visual consistency from reliable blocks. For example, a dramatic but controlled black-and-white pattern such as Panda White marble block can be engineered into stair treads and landings when thickness, support spacing, and nosing details are designed correctly. The strong veining needs to be aligned and supported so it becomes a visual asset, not a structural weak point.

Understanding How a Marble Slab Behaves on a Stair

Load Conditions on a Marble Stair Tread

| Load Type | Description | Typical Real-World Examples |

|---|---|---|

| Point Loads | Localised, high-intensity forces applied over a small contact area. Critical for assessing surface crushing and flexural stress. | High heels, luggage wheels, service trolleys, cart wheels, maintenance equipment |

| Dynamic Loads | Moving or impact forces that change direction and magnitude rapidly. These increase stress compared with static loads. | People running, sudden stops, sharp turns on stairs, a person descending while carrying heavy bags |

| Long-Term / Fixture Loads | Continuous or sustained loads connected directly to the stair structure or adjacent elements. | Handrail brackets, balustrades, glass anchors, guardrail fixings, mechanical connections embedded in the tread |

Critical checks include:

-

Flexural strength of the chosen stone

-

Span between supports (stringers, steel angles, concrete rebates)

-

Nosing projection beyond the riser

-

Thickness of the slab and any reinforcement system (e.g. under-slab mesh or backing)

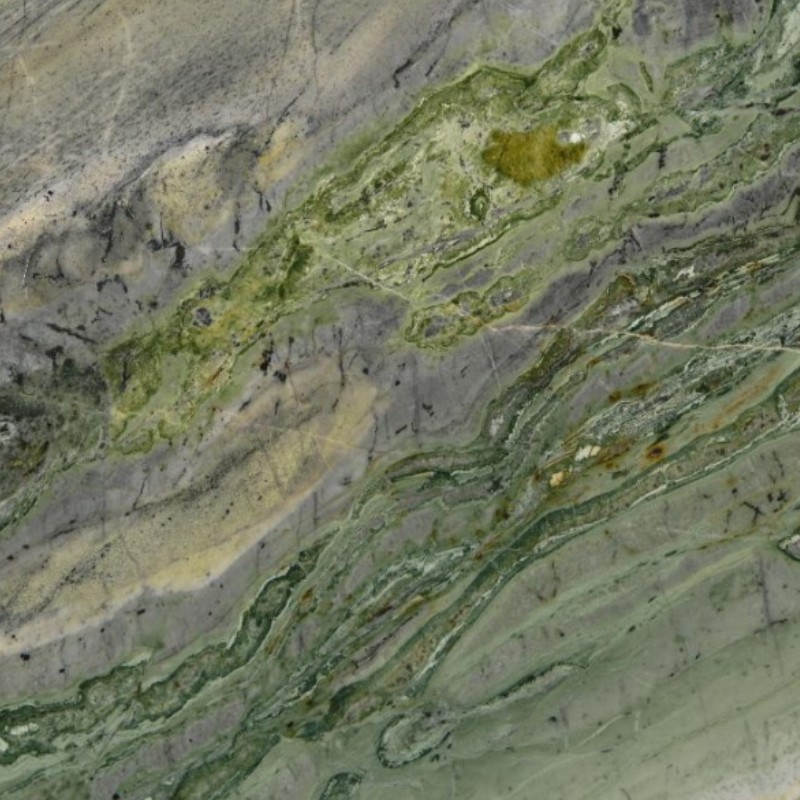

Stair design also has to consider brightness, wayfinding, and visual comfort. In transport projects, for example, codes increasingly recommend clear contrast on nosings and consistent luminance across the tread. That’s where pale, light-reactive stones – such as the white-green tones explored in Ice Connect Marble and Ice Jade marble slab applications – can help create bright, legible stair zones without needing overly harsh artificial light.

Choosing Stone Types and Finishes for Stair Safety

For public stairs, finish matters as much as stone selection. A high-gloss polished marble slab may be beautiful in a wall cladding application, but too slippery for a wet entrance stair.

Successful stair specifications usually combine:

-

Honed or lightly brushed finishes on main treads

-

Textured or grooved nosings for extra grip

-

Carefully positioned matting at entrances to reduce water and grit

-

Cleaning regimes that avoid waxes and sealants which create uneven slip resistance

Darker or more dramatic stones can be used in targeted locations, especially when paired with controlled lighting. Meteor-like dark stones with depth and translucency, such as those showcased in Meteor Granite and Black Vermont luxury natural stone, work well on feature flights or gallery stairs where you want drama – provided the nosing details, lighting, and anti-slip inserts are engineered correctly.

Pattern, Direction, and Reading the Stair From a Distance

People rarely look down at each individual tread; they read the whole stair from three to six metres away. That means your marble slab pattern has to work at both micro and macro scale.

Key design moves:

-

Align major veins in the direction of travel where possible

-

Avoid random orientation of strong patterns that can cause visual “noise”

-

Use calmer slabs on winders and corners, where visual confusion is already higher

When using deep blacks, charcoals, or strong veining at hand level – for example on balustrade caps or stair-adjacent counters – stones like

Nero Marquina black marble slab for table tops can provide continuity between stairs, landings, and adjacent joinery. The same colour family used on stair treads, handrails, and nearby counters creates a cohesive narrative instead of a patchwork of unrelated materials.

Light, Neutral Stones for Everyday Public Staircases

Not every public stair should be dark and dramatic. In schools, hospitals, offices, and libraries, lighter stones often perform better visually over time. They reflect daylight, reduce glare contrast, and create a sense of openness.

This is where calm whites and soft-toned stones come in. A neutral, luminous material such as Castro White marble can be an excellent base for:

-

Main public stairs in civic buildings

-

Vertical circulation in office atriums

-

Education and healthcare interiors where “quiet” materials are preferred

From a performance perspective, stones like these tend to:

-

Show dirt evenly, which makes cleaning more effective

-

Work well with matte metal nosing inserts and contrast strips

-

Remain visually flexible as furniture, signage, and branding change over time

ESTA’s training materials for stone in public projects repeatedly emphasise the importance of this “quiet background” approach, where the stair is designed as part of a larger, calm environment rather than a standalone sculpture.

Why Supplier Networks Matter as Much as Specifications

A perfectly detailed drawing set will still fail if the stone supply chain cannot deliver consistent, well-matched marble slabs. That’s why collaboration between quarry, processor, exporter, and local installer is so important.

International brands like icestone depend on long-term relationships with regional partners who understand both the stone and local construction practice. Companies such as Sunhing Stones act as bridges between overseas quarries and on-site installation teams, helping with:

-

Bundle selection and pre-layout of stair treads

-

Matching slabs across multiple flights and landings

-

Coordinating crate sizes with site access and lifting constraints

For specifiers and contractors, having a clear line of communication makes a huge difference. Early contact – ideally at the design-development stage – allows everyone to align on thickness, finish, and expected tolerances. That’s why project teams are encouraged to contact Sunhing Stones or similar partners as soon as stairs become part of the stone scope, not right before tender.

FAQ: Marble Slabs on Public Staircases

1. Are marble stairs too slippery for public buildings?

Not if they’re specified correctly. Slip resistance depends on finish, cleaning products, and environmental conditions. Honed, brushed, or textured marble slabs with well-designed nosings can meet or exceed typical slip-resistance requirements for public stairs, especially when combined with good entrance matting and drainage.

2. What thickness should a marble stair tread be?

Typical public stair treads in stone range from 30–40 mm, but the correct thickness depends on span, support detail, and the stone’s flexural strength. It’s essential to check span tables or have an engineer review tread dimensions and support conditions, particularly for cantilevered or open-stringer designs.

3. Can marble be used on external public staircases?

Yes, but with more caution. External marble slabs must withstand freeze–thaw cycles, de-icing salts, UV exposure, and water pooling. That usually calls for frost-resistant stones, robust fixing systems, more aggressive textures, and carefully detailed drainage. In many climates, granite or other dense stones may still be preferred for fully exposed stairs.

4. How do I avoid visible cracking on marble stairs?

Cracks often occur where load paths and veining lines intersect badly – for example, a nosing with a major vein running through it and insufficient support below. Good practice includes: aligning veins carefully, avoiding point loads near edges, ensuring full bedding of the marble slab, and detailing steel or concrete supports so they bear evenly across the tread.

5. How early should I involve the stone supplier in stair design?

The earlier, the better. Bringing your stone specialist into the conversation during schematic or design development helps you choose appropriate materials, dimensions, and finishes that match real quarry output. It also reduces the risk of redesign later when you discover the desired slab size or pattern isn’t feasible.

Calacatta White Marble Staircase

Treat Every Marble Stair as Both Structure and Story

Designing durable public staircases with marble slabs is not a matter of “picking a pretty stone and hoping for the best.” It’s a coordinated exercise in structure, safety, lighting, cleaning, and storytelling.

When you:

-

Choose stones with proven performance and reliable quarry sources

-

Match marble slab type and finish to the traffic, climate, and cleaning regime

-

Detail treads, risers, nosings, and supports with engineering discipline

-

Coordinate early with export brands like icestone and regional partners like Sunhing Stones

…you get staircases that do more than look good on opening day. They guide people safely, hold up under real-world wear, and still tell a coherent material story ten years later.

Expert bodies such as ESTA have consistently highlighted these projects in their case study materials: not because the stone is exotic, but because the design teams treated every slab as part of a system. That combination of data-driven decision-making, on-site experience, and careful supplier collaboration is exactly what turns a marble stair from a maintenance risk into a long-term architectural asset.

Designing a successful marble staircase in a public building requires far more than aesthetic judgement. It is an engineering decision supported by material science, structural logic, lighting psychology, and supply-chain reliability. As Dr. Helen Ward, a senior materials specialist from ESTA, notes: “The longevity of a stone staircase depends on how honestly the design team treats the stone — not as decoration, but as a load-bearing component with predictable behaviour.”When project teams adopt this mindset, everything changes: veining becomes a load path to respect rather than a pattern to admire; finishes become performance tools; and supplier partnerships become essential safeguards for consistency. The most reliable public staircases documented in European and Asian case studies all share the same DNA — early collaboration, conservative detailing, and rigorous testing.

Handled this way, a marble staircase is no longer a maintenance risk. It becomes a civic asset: durable, legible, safe, and still beautiful after a decade of schoolkids, trolleys, and cleaning crews.

Feature Product

-

Four Season Grey Natural Marble Slabs and Tiles

Four Season Grey Natural Marble Slabs and TilesThe Charm of Four Season Pink Good size for ...

-

Panda Green White Luxurious Quartzite Stone

Panda Green White Luxurious Quartzite StoneArtistic Conception Like moonlight piercing ...

-

Vivid Brilliant Natural Marble of Prague Green

Vivid Brilliant Natural Marble of Prague GreenHow to pack and load ? 1. Fumigated wooden b...