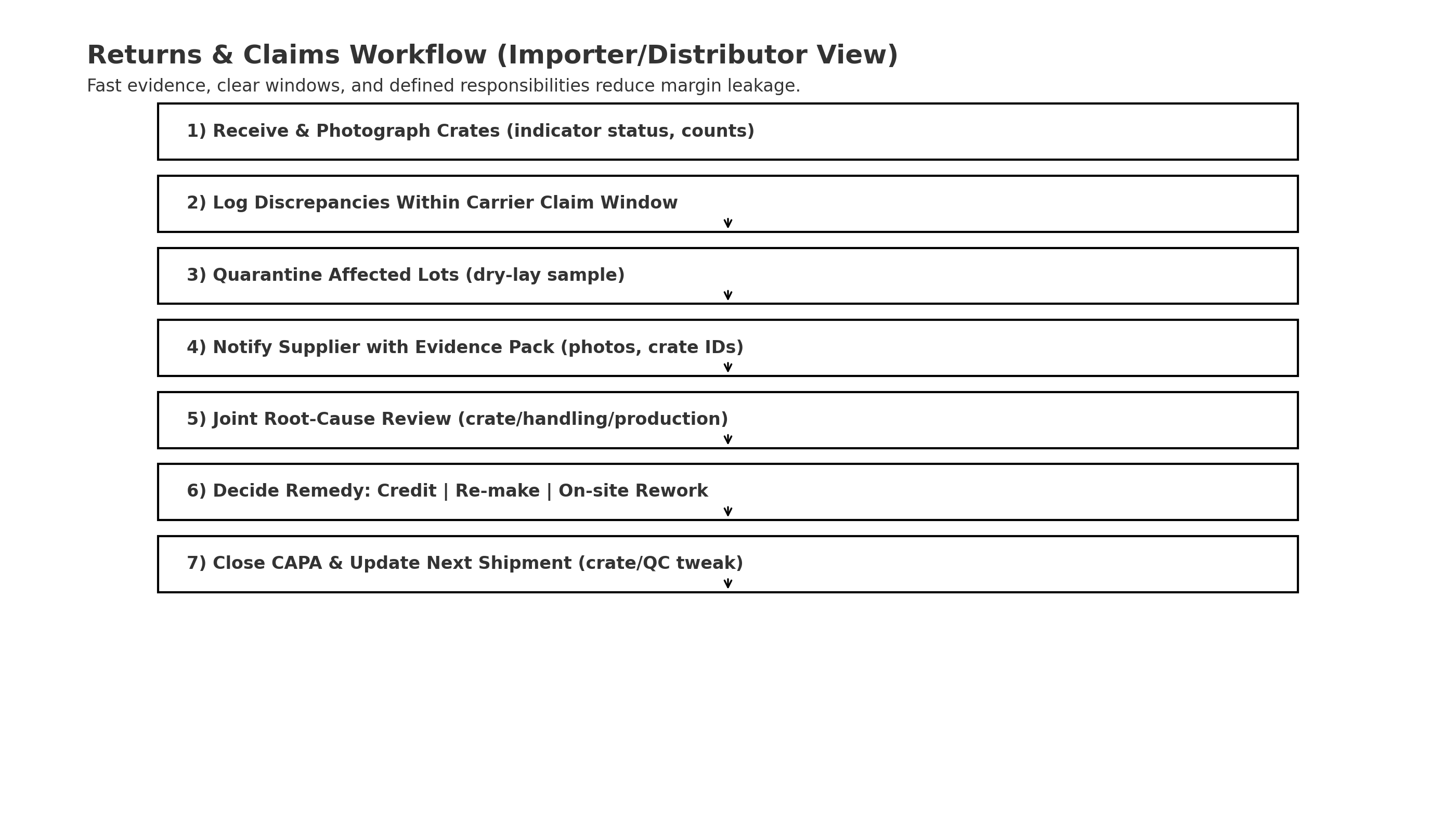

Buying Ice Connect Marble in Bulk: Exporting Tips and OEM Insights

Ice Connect Marble application scenarios are all from ICE STONE

Buyer (Eva): “We want the cool, icy veining for a hotel + residential mix. My fear is color mismatch, breakage, and customs holdups. How do we scale safely?”

Supplier PM (Noah): “Start with quarry‑locked samples and a layout intent. Build QC into three moments—pre‑cut slab selection, mid‑production audit, and pre‑shipment inspection. Then pick Incoterms that match your risk appetite. I’ll map it step by step.”

1) Understand the Material You’re Scaling

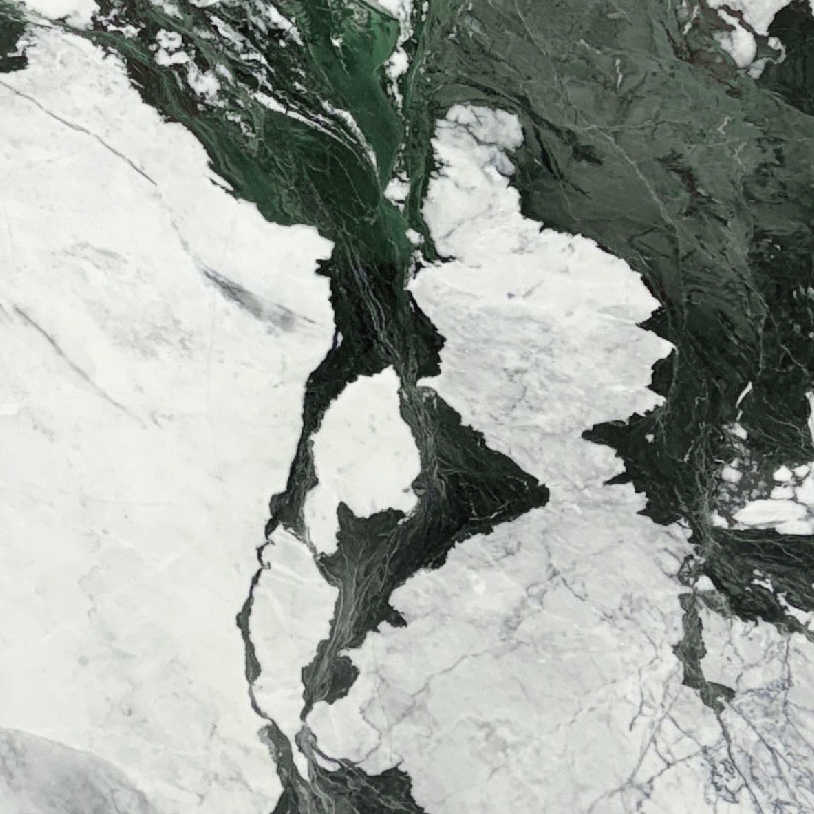

What is Ice Connect Marble? A premium, cool‑toned marble with tight, crystalline veining that reads modern in both bright and low‑light scenes. Best for lobbies, feature walls, bathrooms, stairs, countertops, and backlit panels where bookmatching elevates the space.

Performance signals to request: water absorption; compressive and flexural strength (panel sizing, tread loads); abrasion resistance (public areas); wet slip ratings for floor finishes; freeze–thaw/salt testing if the project climate requires it.

When to reconsider: continuous immersion, aggressive acids, or heavy industrial abrasion. For wet barefoot decks, combine honed + micro‑texture finishes and verify slip ratings.

Spec tip: Always specify by quarry / bed / cut orientation (vein‑cut vs cross‑cut) / finish and approve an acceptable colour‑range matrix. Reserve 2–5% attic stock for future maintenance.

2) Sourcing Strategy: From Sample Kit to Lot Reservation

- Quarry mapping: ask for quarry origin, bed ID, recent lot photos (dry/wet), and prior project references.

- Grade taxonomy: define A/B/C cosmetic grades (cloudiness, inclusions, veining rhythm) with photographs.

- Sample kits: 200×200×20 mm swatches in all requested finishes; include a gloss meter value for polished, slip value for textured.

- Mockups: wall and floor mockups with your intended joint width, edge chamfer, and grout colour to set aesthetic expectations.

- Lot reservation: tag slabs with QR codes; freeze the selection list inside the PO to avoid silent substitutions.

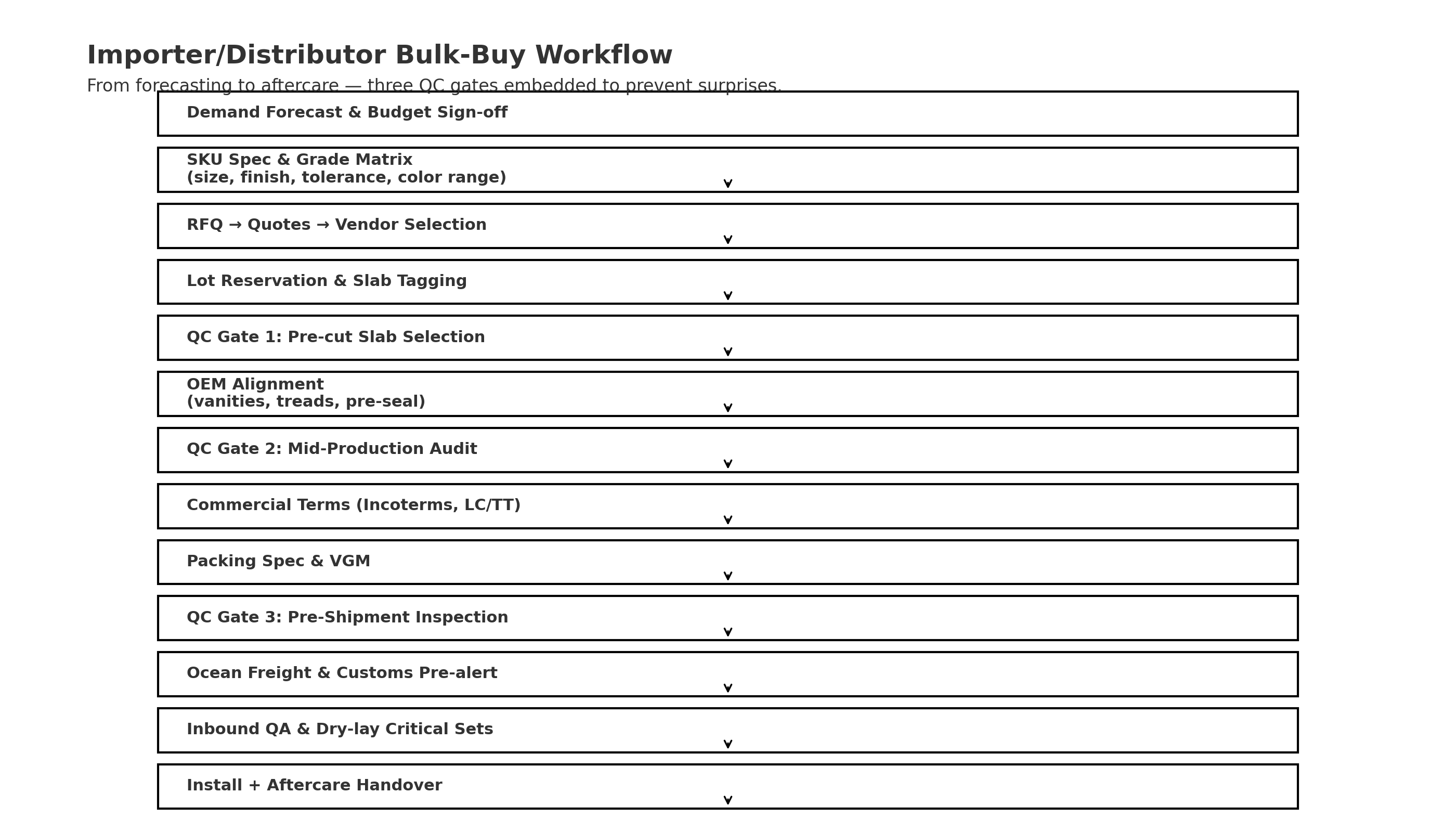

Ice Connect Marble bulk-buy workflow with three QC gates from forecast to aftercare

3) OEM/ODM Options That Save Time Onsite

- Pre‑fabricated vanities: sink + faucet cutouts, splashbacks, pre‑sealed honed surfaces, under‑mount reinforcement strips.

- Stair systems: treads with anti‑slip nosing, risers, and landings cut to module; repeatable nosing radii for safety.

- Feature walls: numbered, bookmatched sets (2‑way/4‑way) with layout maps; backlit‑ready panels with milled slots for LED carriers.

- Edge engineering: eased/chamfered arrises (2–3 mm) to reduce site chipping; CNC profiling for reception desks or niches.

- Factory pre‑seal: breathable penetrating repellent tailored to finish; include SDS and maintenance cards.

- Crate branding: logo stencils, QR packing lists, and photo manifests—faster receiving and fewer site mix‑ups.

Finish pairing cheat‑sheet: polished for vertical drama; honed/leathered for floors to control glare; micro‑bush or relief texture for wet or sloped areas.

4) Commercial Architecture: Terms That Prevent Surprises

Lead‑time anatomy: block selection → slab cutting → fabrication → pre‑seal → packing → container booking → sailing → customs → last‑mile. Align this with project milestones (dry‑in, FF&E, turnover).

Incoterms at a glance (choose by control vs convenience):

| Incoterm | Who books main freight | Risk transfer point | Use when… |

|---|---|---|---|

| EXW | Buyer | Seller’s gate | You have strong local agents and want full control. |

| FOB | Buyer (ocean) | On board at origin port | The industry default for stone; transparent claims. |

| CIF | Seller | Ship’s rail (insurance included) | You want simpler buying but still ocean freight visibility. |

| DDP | Seller | Your site | Turnkey delivery; confirm the seller’s import competence. |

Payment norms: deposit + balance against copy B/L or FCR; LC for large programs. Surcharges to watch: peak season, war‑risk, low‑sulphur fuel, congestion, storage/demurrage.

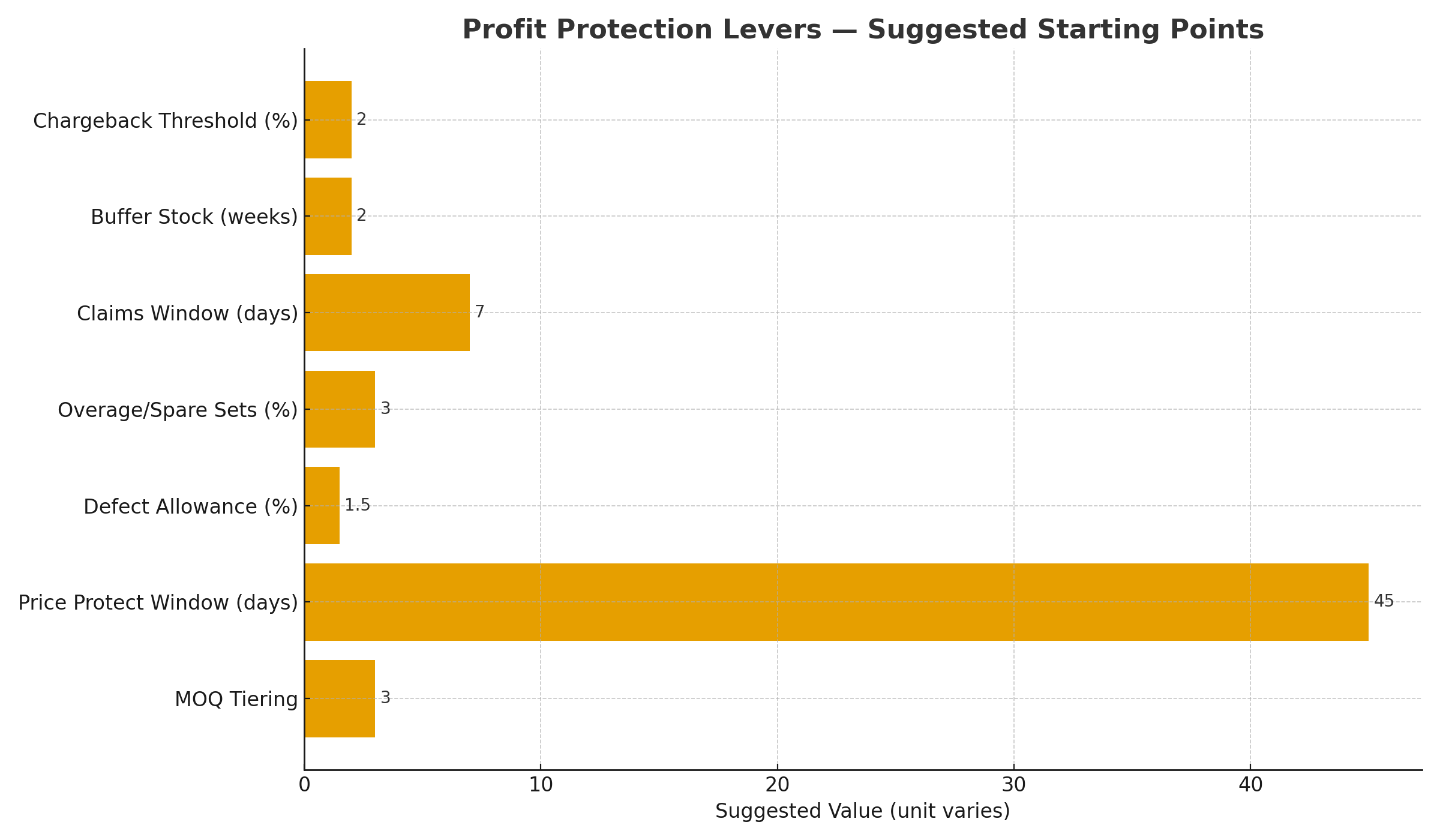

Profit protection levers for marble importers: MOQ tiering, price-protect window, defect allowance, spare sets, claims window, buffer stock

5) Risk Matrix (Plan Before It Happens)

| Risk | Trigger | Prevention | Mitigation |

|---|---|---|---|

| Colour mismatch | Lot switch, mixed finishes | Lock slab list; photo manifest; segregated crates | Tag by zone; use attic stock; targeted re‑fabrication |

| Breakage in transit | Poor crate design, rough handling | ISPM‑15 crates, corner guards, shock/tilt indicators | Insurance + photographic evidence; salvage plan |

| Customs delay | HS code error, missing docs | Pre‑clear docs; broker pre‑alert; correct HS 6802.* | Switch to telex release; pay storage proactively |

| Slip incidents | Wrong finish in wet zones | Verify slip ratings; mockup testing | Site signage; emergency etching/micro‑texture |

| Moisture staining | No drip edges; trapped vapour | Design falls/drips; breathable pre‑seal | Controlled dry‑out; reseal; detail correction |

6) QC Program: Three Gates + AQL Sampling

Gate 1 — Pre‑cut slab selection: approve range and reject outliers before cutting. Take front/back photos and record slab numbers.

Gate 2 — Mid‑production audit (FAT‑light): sample modules for dimensions, flatness, edge quality, finish uniformity, and verify pre‑seal evenness. Correct deviations while the line is running.

Gate 3 — Pre‑shipment inspection (PSI): AQL sampling by crate. Verify packing integrity (foam, spacers, strapping), random moisture meter checks, and crate drop‑test on a sacrificial unit.

AQL primer: For appearance/dimensions, many buyers use AQL 2.5–4.0. Define critical (CR), major (MA), minor (MI) defects with photo examples. Keep a simple accept/reject rule in the PO.

Measurement discipline: calibrated calipers, straightedges, gloss meters; inspector sign‑off on each crate label. Archive photos in the cloud and embed QR codes in the packing list.

7) Packaging & Containerization: Zero‑Drama Crates

- Crate build: kiln‑dried, ISPM‑15 stamped timber; internal steel/ply stiffeners for large panels.

- Layering: foam sheets between pieces, corner/edge protectors, cross‑bracing; nylon straps with buckle guards.

- Moisture control: inner PE liner + desiccant bars; keep crates on skids off the container floor.

- Markings: PO, crate no., net pcs, gross/net weight, dimensions, destination, handling icons (fragile/up).

- Load plan: weight low and centered; avoid cantilevering; lash per carrier rules; include VGM (verified gross mass).

- Shock/tilt indicators: cheap, high ROI for long multi‑modal routes and claim substantiation.

Pro move: Add a QR “uncrating sequence” video link on each crate. Receiving teams love it; damages drop.

8) Export Documents & Compliance (What Customs Expects)

- Commercial Invoice & Packing List (piece count, dimensions, HS 6802.* for marble).

- Certificate of Origin (chamber/FTAs as applicable).

- Bill of Lading (B/L) or Forwarder’s Cargo Receipt (FCR); consider telex release to speed pickup.

- Insurance policy (if CIF) with adequate insured value and named assured.

- ISPM‑15 proof for wood packaging.

- Any destination notes: language labeling, country‑specific conformity declarations, or façade anchor data where required.

9) Logistics Timeline (Anchor to Your Program)

- D‑30 to D‑21: RFQ freeze; quarry pics; mockup approval.

- D‑20 to D‑10: Slab reservation; PO placed; production slot assigned.

- D‑9 to D‑1: Cutting/finishing; Gate 2 audit mid‑way; crate build.

- D‑0: PSI; container loading; VGM filed; sailing window confirmed.

- D+1 to D+20/35: Ocean leg; broker pre‑alert; arrival notice.

- D+X: Customs clearance; last‑mile delivery; inbound QA; installation.

10) Inbound QA & Site SOP (Destination Side)

- Receiving: photo crates on arrival; check shock/tilt indicators; report discrepancies within the carrier’s claim window.

- Acclimation: store flat on dunnage in a dry, shaded zone; avoid rapid temperature swings before install.

- Pre‑install checks: confirm lot/finish match by zone; dry‑lay critical patterns; verify edge arrises and dimensions before permanent fixing.

- Install discipline: correct adhesives/mortars; movement joints; drip edges; slope on horizontals.

- Aftercare handover: neutral‑pH cleaners, breathable repellents (if used), and a 6–12 month inspection note.

11) Sustainability & ESG Talking Points

- Local/regional quarrying reduces transport emissions where feasible.

- Long service life + repairability outperforms short‑cycle materials.

- Waste minimization: optimized cut plans; reuse of offcuts for skirtings or stair risers.

- Water & chemistry: closed‑loop factory water, low‑VOC sealers, and SDS disclosure.

- Project credits: heat‑island mitigation (light colours), responsible sourcing documentation, and potential circular take‑back of crates.

12) Cost Drivers (Value Without Pricing)

- Block quality and yield; cut orientation; finish complexity; size tolerance tightness; defect culling rate; crate engineering; distance to port; sailing season.

- Value engineering ideas: rationalize modules (e.g., 600×1200 mm), prefer honed over high‑gloss in high‑touch areas, standardize nosing radii and edge chamfers across zones.

13) Three Micro Case Notes

- Hotel Lobby (EU): 2‑way bookmatched feature wall, numbered sets with QR layouts; install saved ~18% time vs. previous projects; zero crate damages reported.

- Resort Pool (MEA): honed floors + micro‑bush treads; factory pre‑seal; no slip incidents first season; maintenance frequency reduced.

- Residential Tower (NA): 600 vanity tops OEM‑cut; chamfered arrises eliminated punch‑list chips; turnover two weeks early.

14) RFQ & PO Checklist (Copy/Paste)

- Quarry + bed + cut orientation + finish (with photos)

- Colour‑range acceptance matrix and exclusion rules

- Dimensional schedule + tolerances; edge profiles; joint width assumption

- Layout intent for bookmatch/end‑match; overage %

- Independent tests (absorption, strength, abrasion, slip; freeze/salt if required)

- OEM scope (pre‑seal, vanities, treads, backlit prep)

- Packing spec (crate drawings, ISPM‑15, desiccant, labels, shock/tilt indicators)

- Incoterm, port pair, sailing window; insurance responsibility

- Inspection plan (AQL levels; Gate 1/2/3 sign‑offs)

- Document pack (CI/PL/COO/B‑L, fumigation proof)

- Aftercare kit (cleaner, repellent, SDS, maintenance card)

- Attic stock (2–5%) and slab tagging plan

15) KPI Dashboard (Keep the Program Honest)

- Quality: % lots passing first‑time PSI; defects per 100 m²; crate damage rate.

- Schedule: on‑time production slot adherence; days from PSI to sailing; customs clearance lead time.

- Cost control: demurrage/storage hours; re‑work %; variance vs. planned container count.

- Sustainability: crate reuse rate; offcut utilization %; VOC disclosure completeness.

16) Claims & Change Control (When Things Go Sideways)

- Evidence pack: photos at receipt, crate numbers, indicator status, surveyor report if needed; lodge claim within carrier window.

- Root‑cause review: crate engineering, handling, loading, road segment; implement corrective action in the next shipment.

- Change control (ECO): any shift in finish, module, edge, or layout requires an Engineering Change Order with updated drawings, samples, and schedule impact note.

Returns and claims workflow for imported marble with evidence-first steps and defined windows

17) FAQs (People Also Ask)

Q1. How much overage should I order?

7–12% depending on layout and culling stringency; more for complex bookmatching or on‑site cutting.

Q2. Is factory pre‑sealing worth it?

Yes for honed/leather finishes and tight schedules. Ensure vapour‑permeable chemistry and confirm site slip requirements post‑install.

Q3. What’s the safest Incoterm for first‑timers?

FOB offers transparent freight and claims. Shift to CIF/DDP if you prefer simplicity over control.

Q4. How do I police colour variation?

Approve a range matrix, tag slabs, ship numbered sets, and keep attic stock. Reject outliers at Gate 1—not after arrival.

Q5. Which tests matter most for façades?

Absorption, flexural strength, freeze–thaw (climate), and anchor design to local code; consider salt crystallization in coastal projects.

Q6. Typical production lead time?

From slab reservation to PSI can span several weeks; bake a realistic sailing window into the PO.

Q7. Can I mix finishes in one container?

Yes—crate by finish and zone; use bold labels and QR packing maps to avoid site errors.

Q8. Are shock/tilt indicators necessary?

Cheap insurance for long routes; they also clarify liability when handling goes wrong.

Q9. How do I set AQL levels?

Use AQL 2.5–4.0 for appearance/dimensions, tighter for matched wall sets. Define CR/MA/MI with photos to avoid argument.

Q10. What’s the inbound QA SOP?

Photo crates, verify counts, inspect a sample per crate, dry‑lay critical sets, document any variance, and escalate within claim windows.

Ready to spec Ice Connect Marble for your project? Share your module list, finish plan, and chosen Incoterm. We’ll return a crate plan, QC milestones, and a sailing window within two business days.

Feature Product

-

Four Season Grey Natural Marble Slabs and Tiles

Four Season Grey Natural Marble Slabs and TilesThe Charm of Four Season Pink Good size for ...

-

Panda Green White Luxurious Quartzite Stone

Panda Green White Luxurious Quartzite StoneArtistic Conception Like moonlight piercing ...

-

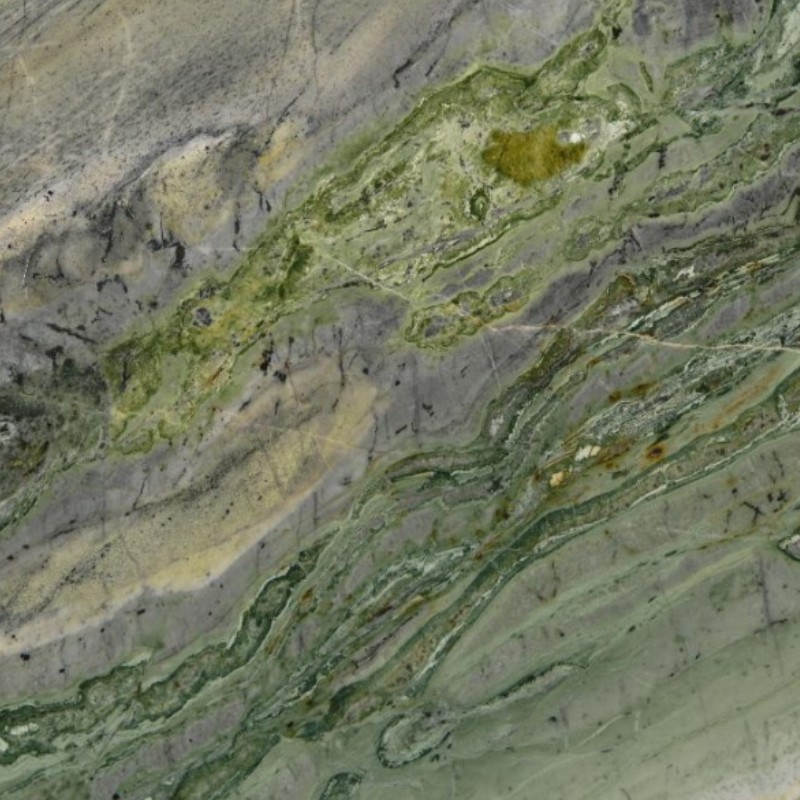

Vivid Brilliant Natural Marble of Prague Green

Vivid Brilliant Natural Marble of Prague GreenHow to pack and load ? 1. Fumigated wooden b...